Here comes the bearing disassembly! Non-destructive disassembly! Any bearing can be dismantled like this!

Here-comes-the-bearing-disassembly-non-destructive-disassembly-any-bearing-can-be-dismantled-like-this!

There is all kinds of hydraulic pump and parts, engine and parts need to use bearing, and we could supply all kinds of bearing for you. However, when you have problems, how to dismantle in non-destructive way.

Reasonable disassembly of the bearing in the case of interference fit is the core of bearing disassembly technology. When the disassembly force is so large that it cannot be dismantled by ordinary methods, and the disassembly force produced by conventional methods is likely to damage the bearing, an oil hole is generally designed at the end of the shaft, the oil hole extends to the bearing position and then penetrates radially to the shaft surface An annular groove is added, and a hydraulic pump is used to pressurize the inner ring to expand the inner ring during disassembly to reduce the disassembly force. For small bearings mounted on adapter sleeves with straight shafts, a hammer can be used to remove small steel blocks that evenly act on the end face of the bearing inner ring (Figure 7). For bearings mounted on adapter sleeves with stepped shafts, the use of hydraulic nuts can make bearing removal easier.

After the bearing has been running for a period of time, there will inevitably be needs for maintenance or damage replacement. In the early development of the machinery industry, the popularity of professional knowledge was insufficient, and the awareness of safe operating procedures was insufficient. Today we will only talk about the disassembly of bearings .

See how the so-called disassembles the bearing, and it's done in a second.

The above is really a common practice of some people in real work. The efficiency is high. Maybe you sometimes really have no damage. But have you considered that there is no injury on the bearing surface, but is there any injury inside?

In addition, the bearing steel is relatively hard and brittle, and it is easier to smash under gravity. The consequences are disastrous. I am afraid that everyone feels bad.

Some cases of stinging are no longer on the top. Scientific operating procedures and tools are required for bearing installation and disassembly, so as to make a bearing more perfect.

There are also many skills and knowledge about how to dismantle the bearing accurately and quickly. This article summarizes it in detail.

Safety first

Any operation must be based on safety, and bearing removal is no exception. At the end of use, the bearing is likely to wear to a certain extent. In this case, if the disassembly method is improper and the external force is applied unreasonably, it is very likely to cause the bearing to break and the metal fragments to splash and bring danger. It is strongly recommended to add a protective blanket to cover the bearing during disassembly to ensure safe operation.

Classification of bearing disassembly

In the case of correct support dimension design, as long as the bearings with clearance fit are not deformed or rusted due to excessive use and are stuck on the mating parts, the orientation can be removed. Reasonable disassembly of the bearing in the case of interference fit is the core of bearing disassembly technology. Bearing interference fit is divided into inner ring interference and outer ring interference. The following two cases will be introduced separately.

First, the inner ring of the bearing is interference, and the outer ring clearance fits

1.Cylinder shaft

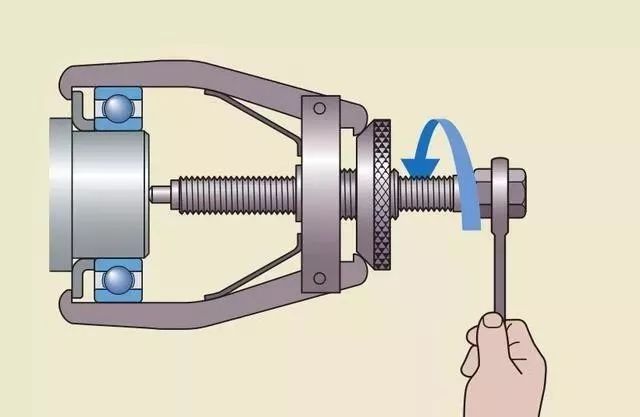

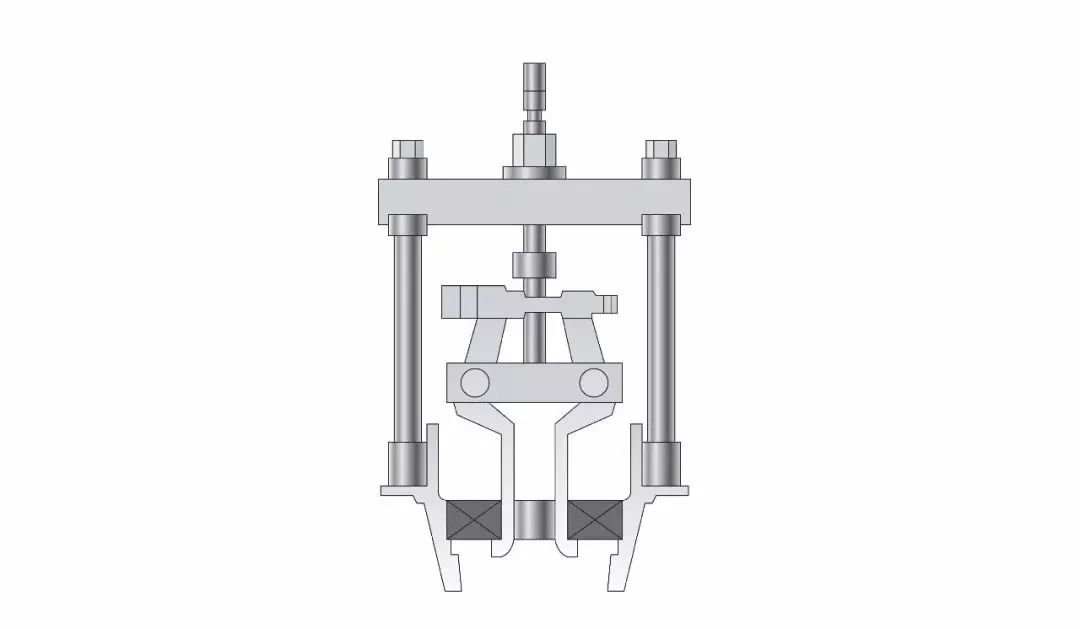

Proper bearing disassembly cannot be separated from the use of tools. For small size bearings, the conventional tool is a puller. The puller is divided into two jaws and three jaws, which are divided into thread and hydraulic.

The thread puller is a more traditional tool. Its operation is to align the center screw with the center hole of the shaft, and apply a small amount of grease to the center hole of the shaft. The bearing can be pulled out. The hydraulic puller uses a hydraulic device instead of a thread. When the middle piston is continuously extended, the bearing will be continuously pulled out, which is faster than the traditional screw puller and the hydraulic device can quickly retract.

In some designs, the distance between the end face of the bearing inner ring and other components is small, and there is no operating space for the traditional puller claws. At this time, a two-piece plywood (as shown in the figure below) can be used. Select a suitable size of the plywood for disassembly pressure. Part of the splint can be made relatively thin, so as to penetrate into a narrow space.

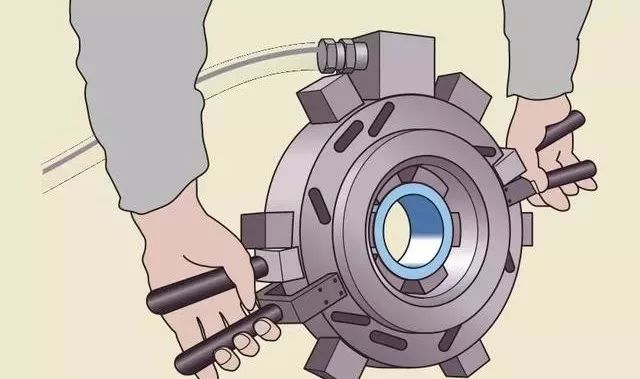

When there is a large number of small size bearings that need to be disassembled, a quick disassembly hydraulic device can also be used (as shown below).

When there is a large number of small size bearings that need to be disassembled, a quick disassembly hydraulic device can also be used (as shown below).

▲ Quick disassembly hydraulic device

▲ Quick disassembly hydraulic device

There is also a special mobile disassembly device for the disassembly of the integral bearing of the railway vehicle axle.

▲ Mobile disassembly device

When the size of the bearing increases, the force required to disassemble the bearing also increases, and the universal puller cannot be applied, and special tooling needs to be designed for disassembly. The minimum force required for disassembly can be estimated according to the installation force required for the bearing to overcome the interference fit, and the calculation formula is as follows:

F = 0.5 * π * u * W * δ * E * (1- (d / d0) 2)

F = force (N)

μ = coefficient of friction between the inner ring and the shaft, generally about 0.2

W = inner ring width (m)

δ = interference fit (m)

E = Young's modulus 2.07x1011 (Pa)

d = bearing inner diameter (mm)

d0 = Inner ring outer raceway middle diameter (mm)

π = 3.14

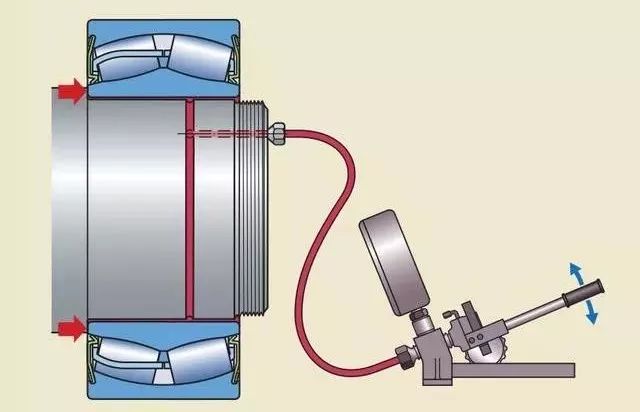

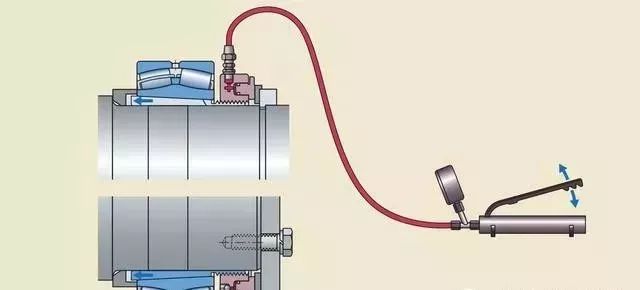

When the disassembly force is so large that it cannot be dismantled by ordinary methods, and the disassembly force produced by conventional methods is likely to damage the bearing, an oil hole is generally designed at the end of the shaft, the oil hole extends to the bearing position and then penetrates radially to the shaft surface. An annular groove is added, and a hydraulic pump is used to pressurize the inner ring to expand the inner ring during disassembly to reduce the disassembly force.

When the size of the bearing is too large and the simple hard-pull type can no longer be disassembled, a heating disassembly method is required. Before operation, you need to prepare a complete set of tools, such as jacks, height rulers, spreaders and so on. The heating disassembly operation method is to directly wind the coil onto the inner ring's raceway to heat and expand it, so that the bearing is easily disassembled. Roller separable cylindrical bearings also apply the same heating method. This method can remove the bearing without damage.

▲ Heat disassembly method

2.Tapered shaft

Because the areas of the two end faces of the inner ring of the tapered bearing are significantly different, the large end faces of the inner ring of the bearing are usually disassembled by heating. The flexible coil intermediate frequency induction heater is used to quickly dismantle the bearing inner ring by heating the bearing inner ring to a sufficient temperature difference with the shaft. Because tapered bearings are used in pairs, after removing one inner ring, the other inner ring must be exposed to heat. If the bearing inner ring is placed at a position where the large end face cannot be heated, the cage needs to be destroyed, the rollers must be removed to expose the inner ring body, and the coil can be directly placed on the raceway for heating.

▲ Flexible coil intermediate frequency induction heater

The setting of the heater heating temperature must not exceed 120 degrees Celsius, because the bearing disassembly requires a rapid temperature difference and operation process, not the temperature. If the ambient temperature is high or the interference amount is very large, and the temperature difference is insufficient, dry ice (solid carbon dioxide) can be used as an auxiliary means. Dry ice is placed on the inner wall of the hollow shaft to quickly reduce the shaft temperature (such large-sized workpieces are generally) , Thereby increasing the temperature difference.

For disassembly of tapered bore bearings, do not completely remove the clamping nut or mechanism at the end of the shaft before disassembly, just loosen it to avoid bearing falling accidents.

The removal of large-size tapered shafts requires the removal of oil holes. Take rolling mill tapered bore four-row tapered bearing TQIT as an example. The bearing inner ring is divided into three parts, two single-row inner rings and a double inner ring in the middle. There are three oil holes at the end of the roll, corresponding to the identification 1, 2,3, where 1 is the inner ring corresponding to the outermost, 2 is the double inner ring corresponding to the middle position, and 3 is the inner ring with the largest inner diameter. When disassembling, disassemble according to the serial number, and pressurize the holes 1, 2, and 3 progressively. When the bearing can be hoisted after the vehicle is completed, the hinge ring at the end of the shaft is removed, and the bearing is removed.

If the bearing needs to be used again after disassembly, the force applied during disassembly must never be transmitted through the rolling elements. For split bearings, the bearing ring with the rolling-body cage assembly can be removed separately from the other bearing ring. When disassembling non-separated bearings, the bearing rings with clearance fit should be removed first. To remove bearings with interference fit, different tools should be used according to their type, size and fit.

Remove bearings mounted on a cylindrical shaft diameter

Cold disassembly

figure 1

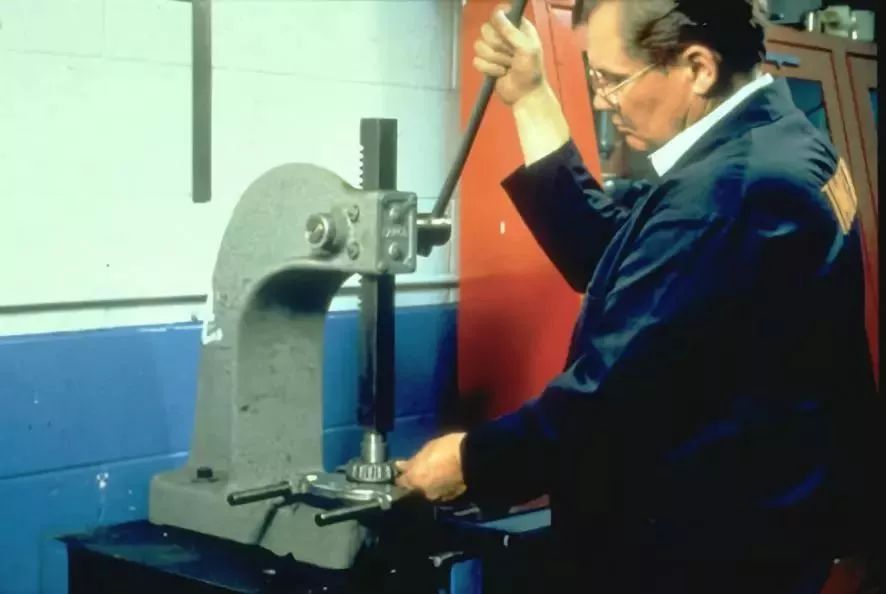

When removing smaller bearings, the bearing ring can be removed from the shaft by lightly tapping the side of the bearing ring with a suitable punch, and a mechanical puller is better used (Figure 1). The pull should be applied to the inner ring or adjacent parts. If the shaft shoulder and the bearing seat shoulder are provided with grooves to accommodate the puller grip, the disassembly process can be simplified. In addition, some threaded holes are machined at the shoulder of the hole to facilitate the ejection of the bearing by the bolt (Figure 2).

figure 2

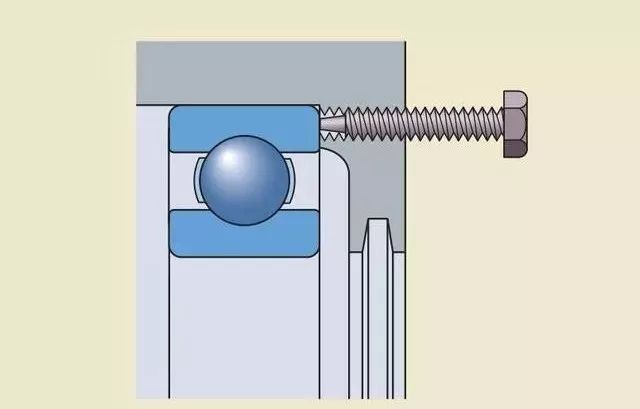

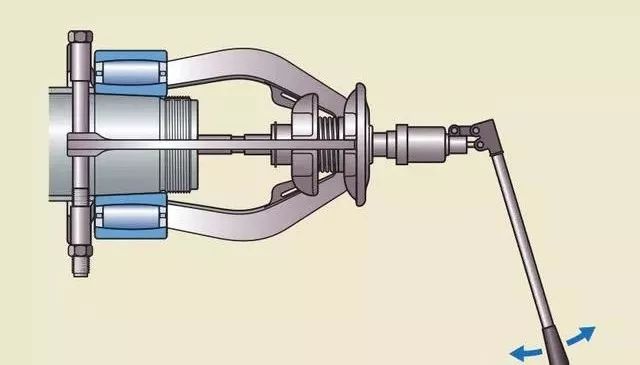

Large and medium-sized bearings usually require more force than machine tools can provide. Therefore, it is recommended to use hydraulic power tools or oil injection methods, or both. This means that oil holes and grooves need to be designed on the shaft (Figure 3).

image 3

Hot disassembly

When removing the inner ring of a needle roller bearing or NU, NJ, and NUP type cylindrical roller bearings, a thermal disassembly method is suitable. Two commonly used heating tools: heating ring and adjustable induction heater.

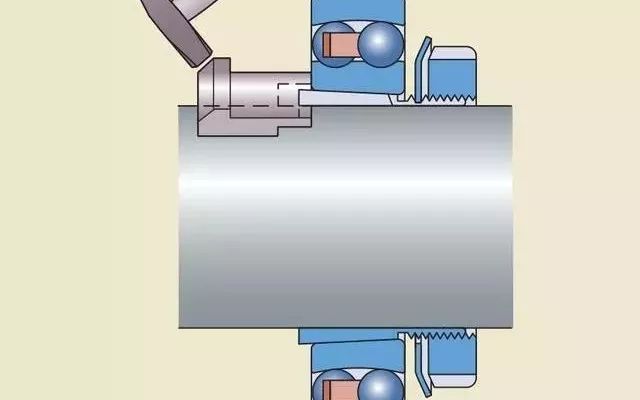

The heating ring is usually used to install and remove the inner ring of small and medium-sized bearings of the same size. The heating ring is made of light alloy. The heating ring has a radial slot and is equipped with an electrically insulated handle (Figure 4).

Figure 4

If you frequently remove inner rings of different diameters, a debuggable induction heater is recommended. These heaters (Figure 5) quickly heat the inner ring without heating the shaft. When removing the inner ring of a large cylindrical roller bearing, some special fixed induction heaters can be used.

Figure 5

Remove bearings mounted on a conical shaft diameter

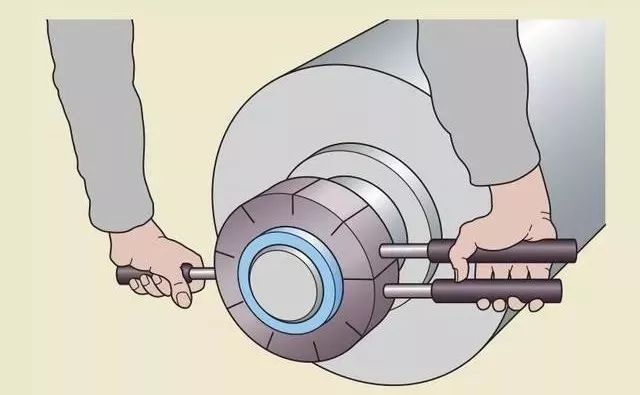

Small bearings can be removed by holding the inner ring with a mechanical or hydraulic booster. Some pullers are equipped with a spring-operated arm. Using this self-centering puller can simplify the process and avoid damage to the journal. If the puller claw cannot be used on the inner ring, the bearing should be dismantled through the outer ring or by a puller combined with a pull tab (Figure 6).

Figure 6

When using the oil injection method, the removal of medium and large bearings will be safer and easier. This method injects hydraulic oil between two conical mating surfaces through oil holes and oil grooves under high pressure. The friction between the two surfaces is greatly reduced and an axial force is created that separates the bearing and shaft diameter.

Remove the bearing on the adapter sleeve

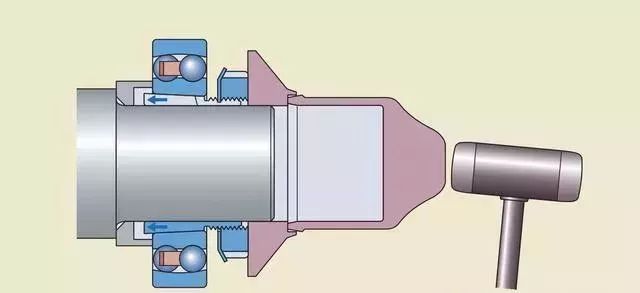

For small bearings mounted on adapter sleeves with straight shafts, a hammer can be used to remove small steel blocks that evenly act on the end face of the bearing inner ring (Figure 7). Prior to this, loosen the adapter sleeve lock nut several turns.

Figure 7

Small bearings mounted on adapter sleeves with stepped shafts can be removed with a hammer by tapping the small end face of the adapter sleeve lock nut with a special sleeve (Figure 8). Prior to this, loosen the adapter sleeve lock nut several turns.

Figure 8

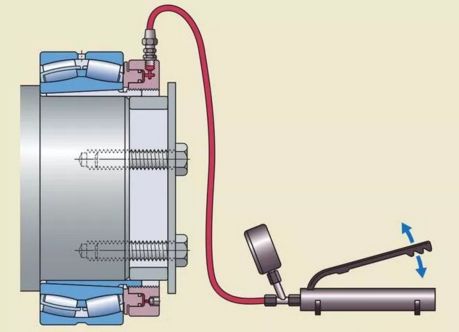

For bearings mounted on adapter sleeves with stepped shafts, the use of hydraulic nuts can make bearing removal easier. To this end, a suitable stopper must be installed close to the piston of the hydraulic nut (Figure 9). The oil filling method is a simpler method, but an adapter sleeve with an oil hole and an oil groove must be used.

Figure 9

Remove the bearing on the withdrawal sleeve

When removing the bearing on the withdrawal sleeve, the locking device must be removed. (Such as lock nuts, end plates, etc.)

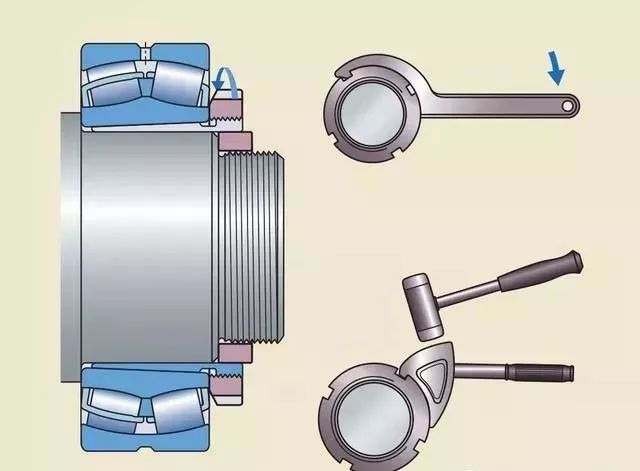

For small and medium-sized bearings, they can be removed using a lock nut, hook wrench, or impact wrench (Figure 10).

Figure 10

For medium and large bearings installed on the withdrawal sleeve, they can be easily removed using hydraulic nuts. A stop is recommended behind the hydraulic nut on the shaft end (Figure 11). The stop device can prevent the withdrawal sleeve and the hydraulic nut from flying out of the shaft when the withdrawal sleeve is suddenly separated from the mating position.

Figure 11 Ting Shaft Bearing

Interference fit of bearing outer ring

The premise of removing the bearing under the condition that the outer ring of the bearing has an interference fit is that the diameter of the outer ring shoulder must not be less than the support diameter required by the bearing. The drawing tool diagram shown below can be used to remove the outer ring.

If the shoulder diameter of the outer ring is required to be completely covered in some applications, the following two design solutions should be considered during the design phase:

• Two or three notches can be reserved on the step of the bearing seat to make the puller claws have a point of force for easy removal.

• On the back of the bearing housing, four penetrating threaded holes are designed to reach the bearing end face. They can usually be sealed with bolts. When disassembling, replace them with long screws. Tighten the long screws to gradually push the outer ring out.

When the bearing is large or the interference is large, a flexible coil induction heating method can also be used. Disassembly by heating the outer diameter of the cabinet. The outer surface of the cabinet should be regular and flat to prevent local overheating. The centerline of the box should be perpendicular to the ground, and if necessary, assisted by jacks.

The above is a general introduction to the method of disassembling bearings for various situations. Due to the wide variety of bearings and the wide range of applications, disassembly procedures and precautions also differ. To meet your needs, please feel free to consult the Timmond Rolling Mill Bearing Engineering Technical Team. We will rely on our professional knowledge and technology to solve various problems for you. I believe that by mastering the correct method of bearing disassembly, you can effectively maintain and replace the bearing and improve the efficiency of equipment operation.

Any seal kits, hydraulic hammer and parts, hydraulic pump and parts, engine parts pls feel free to contact us via email info@wonepart.com or whatsapp:+86-15860751932.