How to store hydraulic seals properly?

How to properly store seals?

Most sealing materials, including vulcanized rubber and other elastomers, often have more or less performance changes during storage. Improper storage methods will accelerate the aging of seals and even cause damage such as cracking of seals, which directly affects seal The life of the pieces.

What factors should we consider when storing seals properly?

1.Temperature

Generally, the storage temperature of the seal should not exceed 50 ° C (120 ° F), and it should be kept below 30 ° C under conditions. Low temperature has no permanent hazard to most rubber products. As long as the rubber products are handled with care, do not hang them or put them under pressure. When removed from low temperature environments, the material temperature should be raised to approximately 30 ° C (70 ° F) before use.

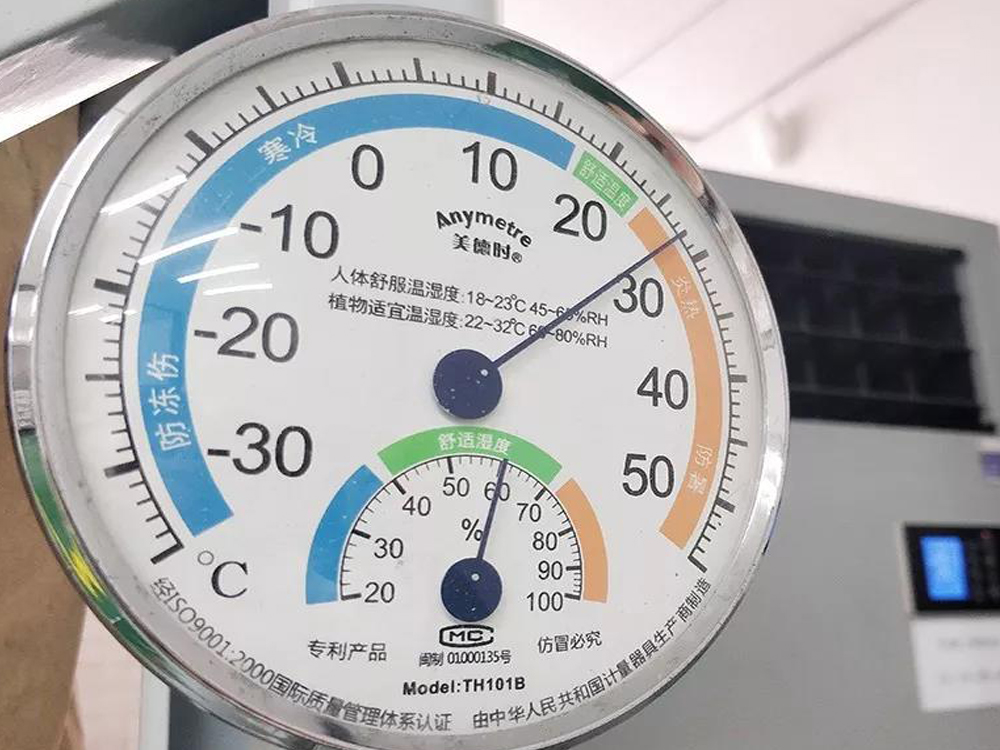

2.Humidity

In an airless environment, the optimal humidity is approximately 65%. In the spring and summer when the humidity is high, it is necessary to control the inventory reasonably, and it is not suitable to store a large amount of inventory products.

3. Light (sunlight, strong artificial light)

It is important to avoid direct sunlight and artificial light with high UV content. Unless stored in opaque packaging, it is recommended to cover the windows with red or orange glass or coating.

4.Oxygen and ozone

Elastic articles should avoid air circulation as much as possible. Since ozone is particularly harmful to rubber, storage facilities should avoid using equipment that may cause electric sparks or discharges. Vulcanized rubber products should be stored in packaging, sealed containers, or other suitable means.

5, deformation

Rubber articles should be stored in a loose, flat state without being pulled or stressed. Avoid hanging or crushing to avoid deformation.

6.Contact with liquid and semi-solid materials

All sealing materials and components should be kept away from liquid and semi-solid materials (especially solvents, such as oil or grease).

7.Contact with metal

Metals such as manganese, iron, and copper or copper alloys can have a deleterious effect on rubber, and can be separated by cardboard or cellophane barriers.

8. Contact with non-metals

In this case, avoid contact with other rubber or phenol oils. Packaging media should also be reasonably selected. For example, PE shrink film packaging materials containing multipliers are not suitable for polyurethane seals. Multipacks contained in PE packaging materials will penetrate into polyurethane and affect the performance of polyurethane.

9, Inventory turnover

Do a good job of inventory management by combining different sealing materials, and try to achieve the same and simultaneous storage. The elastomer should be kept as short as possible and strictly rotated.

10.Clean

Cleaning agents that are harmful to sealing materials are usually organic solvents such as trichloroethylene, carbon tetrachloride, and petroleum. Soap, water and methylated alcohol are the least harmful. All parts should be stored dry at room temperature before use.

11.Storage life

The storage life of seals made of different materials under ideal conditions is as follows: Material Storage

Polytetrafluoroethylene (PTFE) filled polytetrafluoroethylene (F-PTFE) > 10 years

polyurethane (TPU / CPU) 3 years

Nitrile rubber (NBR) hydrogenated nitrile rubber (HNBR) 3 years

Fluoro rubber (FKM) 4 years

Before using and installing the inventory, you should carefully check the following:

*mechanical injury

*Permanent deformation

*Whether there are cracks or surface cracks

*Sticky surface

*Softening / hardening

In addition to these key factors, the size and material of the product must also be combined. The validity period of the assembly should be based on the short-life component.

Yudi Technology Co., Ltd. provides hydraulic (pneumatic) seals,

Available seal size Φ5mm ~ Φ2000mm,

Product features Ultra-low friction, wide temperature range and long life.

If you need more information about our products,Or any problem feedback, please feel free to contact us:

Web:www.wonepart.com

Email: info@wonepart.com

Whatsapp: + 86-15860751932

Contact: jones chen