Steel for hydraulic breaker hammer piston and manufacturing method

Steel for hydraulic breaker hammer piston and manufacturing method

Technique Background :

The hydraulic breaker is a new type of high-efficiency hydraulic shock vibration machine. It is a supporting working part of the excavator or loader. During operation, the high-pressure oil output from the working machine realizes the high-frequency reciprocating motion of the breaker piston in the cylinder. It is used for mining, metallurgical industry, municipal engineering, building construction, road and railway, etc.

Among them, the key parts of the piston breaker, the breaker piston has a continuous high-speed relative reciprocating motion with the cylinder during operation, there is intense friction between the movement reciprocating, and the lower end face frequently hits the drill rod to withstand the impact stress. Therefore, the design and manufacture of the breaker piston directly affects the reliability and life of the breaker work, and the work reliability and life are closely related to the manufacture of the piston material.

In addition, at present, the breaker piston is mostly made of low carbon alloy carburized steel and medium carbon alloy carburized steel, which has the disadvantages of low tensile strength and low core strength after heat treatment of the material, and strong impact on large and medium hydraulic breakers. Under the piston, the piston is prone to blow the end face depression and the end upset phenomenon.

Technical realization elements:

The object of the present invention is to overcome the above-mentioned deficiencies of the prior art and to provide a high-strength and high-toughness hydraulic crusher piston steel and a manufacturing process thereof, thereby avoiding the appearance of the concave center of the piston, greatly reducing the piston fracture condition, and improving the piston. The service life meets the purpose of cost-effective operation.

In order to achieve the above object, the present invention is achieved by the following technical solution: a steel for hydraulic breaker hammer piston, which is a high alloy steel SNCM26VMOD, whose chemical composition is measured by weight percentage mainly including: C=0.14-0.25%, Si= 0.15-0.35%, Mn=0.80-1.20%, Ni=3.25-3.65%, Cr=1.40-1.80%, Mo=0.40-0.60%, V=0.05-0.15%, S≤0.025%, P≤0.025%, The rest are Fe and inevitable impurity elements.

The manufacturing process of the steel for hydraulic breaker hammer piston as described above, the whole process steps include electric arc furnace smelting, LF refining, VD refining, electroslag remelting, forging and post-forging heat treatment.

The process conditions of the process steps are:

1) EAF smelting: the electric arc furnace is used to refine the raw material into molten steel, the molten steel is oxidized and then tapped, and pre-deoxidation and partial alloying are carried out in the ladle;

2) LF refining: LF refining process uses calcium carbide and carbon powder for diffusion deoxidation, white slag retention time ≥ 25 minutes;

3) VD refining: Before the VD refining, the chemical composition is adjusted according to the internal control target value. Under the vacuum degree of 67Pa, the vacuum is kept for ≥30 minutes, and the weak agitation time of the bottom of the ladle is ≥15 minutes. After the steel is sedated, argon is used. Gas protection casting;

4) Electroslag remelting: After the steel ingot obtained by the electric arc furnace smelting, LF refining and VD refining process steps is demolded, the hot slag is remelted, and the electroslag ingot obtained after electroslag remelting is demolded and then cooled to 450. ~500 ° C cover cold;

5) Forging: The electroslag ingot is heated in a vehicle-type gas furnace. The heating furnace temperature is 1230±20°C, the holding time is 2~4h, the initial forging temperature is 1180~900°C, the final forging temperature is ≥800°C, and the hydraulic press is adopted. Wrong protection plate, then upset to H = φ600 ~ φ700mm, on the upper and lower flat anvil to lengthen to the hot side 400mm, the amount of reduction 20% ~ 30%, then pour the eight sides to the hot side 420mm, pour the eight squares back to the furnace insulation 2-4h, the furnace temperature is between 1180 ~ 850 °C, and the furnace is forged by 1800T precision forging machine. The deformation amount of the hammer weight control is 80-100mm per pass.

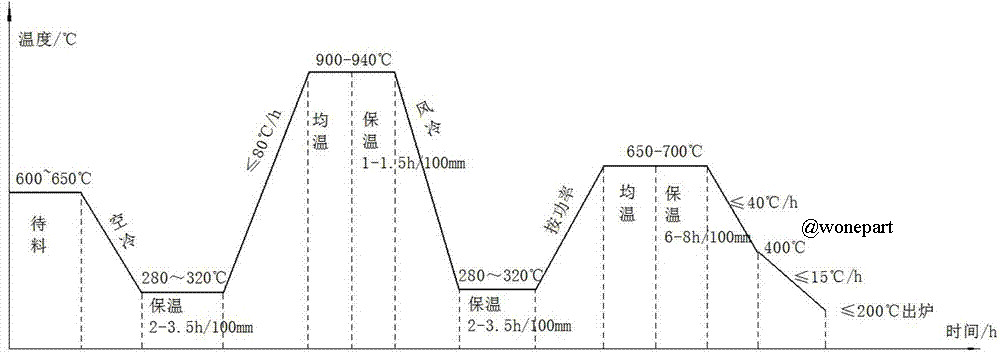

6) Post-forging heat treatment: After-forging heat treatment includes normalizing and annealing process, after forging, air cooling to 280-320 ° C, heat preservation 2 ~ 3.5h / 100mm, and then heating to 900 ~ 940 ° C at ≤ 80 ° C / h speed , heat preservation 1 ~ 1.5h / 100mm, and then air-cooled to 280 ~ 320 ° C, the furnace insulation 2 ~ 3.5h / 100mm, the insulation is raised to 650 ~ 700 ° C after the insulation is slowly cooled, the holding time is 6 ~8h/100mm.

The optimum forging ratio in the forging step is 8 to 10.5.

Compared with the prior technical, the present invention has the following advantages and effects:

SNCM26VMOD alloy steel is used to obtain better toughness by adjusting the content of each element; the above raw materials are refined by LF refining, VD refining, electroslag remelting and other refining steps, and the process of using the piston is studied. , test and forging the influence of material properties, design the best forging ratio: 8 ~ 10.5, eliminating the structural defects of the alloy steel, and making the carbide distribution in the alloy steel uniform; after forging using normalizing + annealing, to achieve The purpose of refining the grain, improving the internal structure and eliminating the forging stress; manufacturing the high-strength and high-resistance piston material by the invention avoids the appearance of the concave center of the piston, greatly reduces the fracture condition of the piston, and improves the service life of the piston.

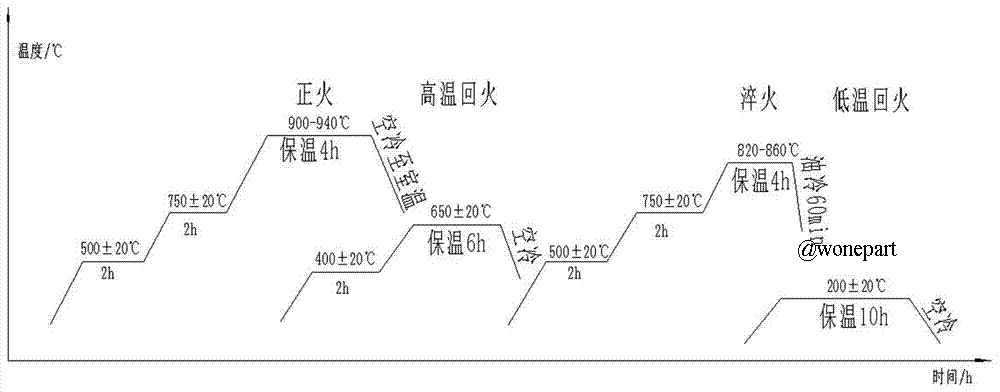

Two φ206mm forgings of different smelting furnaces were taken at the riser end to take a length of 400mm sample, simulating the final heat treatment process, as shown in Figure 2, first normalizing + high temperature tempering to refine the grains and uniform structure. Prepare for quenching. Normalizing 900-940°C, holding for 4h, air cooling, high temperature tempering 650±20°C, holding for 6h, air cooling; quenching 820-860°C, holding for 4h, oil cooling, completing austenite transformation and homogenizing, oil cooling After obtaining the martensite structure; finally, the low temperature tempering is 200±20°C, and the air is cooled after 10 hours of heat preservation to obtain a uniform tempered martensite structure to meet the mechanical properties of high strength and high toughness.

The mechanical properties of SNCM26V piston material and SNCM26VMOD piston material were tested according to GB/T228 and GB/T229 test standards. The results are shown in Table 1 below. The piston material SNCM26VMOD designed by the above chemical composition design, forging ratio design and heat treatment process has better strength and toughness than SNCM26V, which improves the service life of the piston and effectively reduces the production cost.

Technical summary

The invention relates to a steel for hydraulic breaker hammer piston and a manufacturing process thereof, and a steel for hydraulic breaker hammer piston, which is a high alloy steel SNCM26VMOD, whose chemical composition is measured by weight percentage mainly including: C=0.14‐0.25%, Si =0.15‐0.35%, Mn=0.80‐1.20%, Ni=3.25‐3.65%, Cr=1.40‐1.80%, Mo=0.40‐0.60%, V=0.05‐0.15%, S≤0.025%, P≤0.025% The rest are Fe and inevitable impurity elements; the manufacturing process of the steel for hydraulic breaker hammer piston, the whole process steps include electric arc furnace smelting, LF refining, VD refining, electroslag remelting, forging and post-forging heat treatment, through the invention The high-strength and high-resistance piston material is manufactured, which avoids the appearance of the concave center of the piston, greatly reduces the breakage of the piston and improves the service life of the piston.

The database if from Special Steel Technical Paper