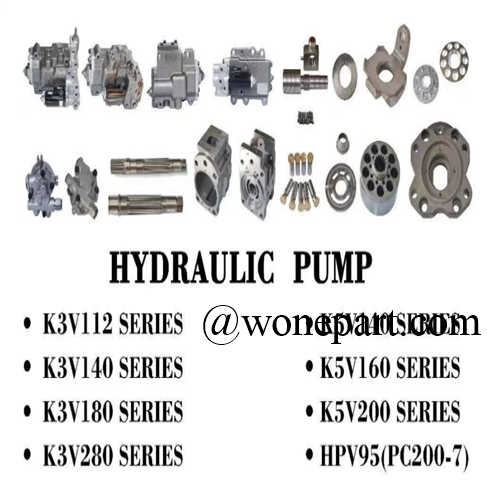

The key part of wonepart hydraulic pump system applied in construction machines

The key part of wonepart hydraulic pump system applied in construction machines

A hydraulic pump is a hydraulic component that provides pressurized liquid for hydraulic transmission, and is a kind of pump. Its function is to convert the mechanical energy of power machines (such as electric motors and internal combustion engines) into liquid pressure energy.

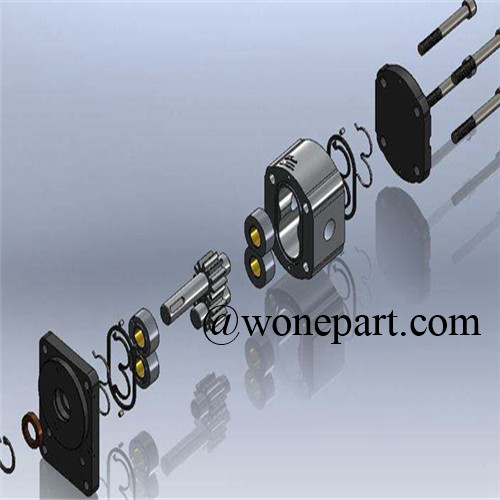

The figure shows the working principle of a single plunger pump. The cam is rotated by a motor. When the cam pushes the plunger upwards, the seal volume formed by the plunger and the cylinder decreases, and the oil is squeezed out of the seal volume and discharged to the place where it is needed through the one-way valve. When the cam rotates to the lower part of the curve, the spring forces the plunger down to form a certain degree of vacuum, and the oil in the oil tank enters the sealed volume under the action of atmospheric pressure. The cam causes the plunger to rise and fall continuously, the sealing volume periodically decreases and increases, and the pump continuously sucks and discharges oil.

1. Hydraulic pump pressure

The working pressure of a hydraulic pump refers to the pressure of the output (or input) oil of the pump (or motor) in actual work, which is determined by the external load.

Rated pressure refers to the highest pressure that can be operated continuously according to the test standard under normal working conditions. Its size is limited by its life. If the pump (or motor) works at a pressure exceeding the rated pressure, the life of the pump (or motor) will be shorter than the designed life. When the working pressure is greater than the rated pressure, it is called overload.

2. Speed

Working speed refers to the actual rotation speed of the pump (or motor) when it is working.

The rated speed refers to the highest speed that can operate normally for a long time under the rated pressure. If the pump exceeds the rated speed, it will cause insufficient oil absorption, vibration and loud noise, and the parts will suffer cavitation damage and shorten the life.

The minimum stable speed refers to the lowest speed allowed for the normal operation of the motor. At this speed, the motor does not crawl.

3. Displacement and flow

Displacement refers to the volume of liquid discharged (or input) obtained by the geometric size of the sealed cavity per revolution of the pump (or motor). The common unit is ml/r (ml/revolution). The displacement can be changed into a variable pump (or variable motor) by adjusting, and a fixed displacement pump (or fixed motor) whose displacement cannot be changed.

The actual flow rate refers to the flow rate at the outlet (or inlet) when the pump (or motor) is working. Due to the internal leakage of the pump itself, its actual flow is less than the theoretical flow. Since the motor itself also has internal leakage, to achieve the specified speed, in order to compensate for the leakage, the actual input flow must be greater than the theoretical flow.

4. Efficiency

Volumetric efficiency refers to the ratio of actual flow to theoretical flow for hydraulic pumps. For hydraulic motors, it refers to the ratio of theoretical flow to actual flow.

Mechanical efficiency, for hydraulic pumps, refers to the ratio of its theoretical torque to the actual input torque. The actual output torque of a hydraulic motor is the torque after the theoretical torque overcomes the friction force, so its mechanical efficiency is the ratio of the actual output torque to the theoretical torque.

The total efficiency refers to the ratio of the output power of the pump (or motor) to the input power. The total efficiency is equal to the product of volumetric efficiency and mechanical efficiency.

As a subsidiary company of Kawasaki Heavy Industries Group, "Kawasaki Precision Machinery Co., Ltd. (KPM)" began the research and development and manufacturing of hydraulic machinery in 1916. After New Year's greetings, hard work and determination, it has already possessed the leading manufacturing scale and production. ability.

Kawasaki Precision Machinery Co., whose core is fluid power, is constantly dedicated to the research and development of new technologies and new products through an excellent R&D team and experimental equipment. At the same time, it makes unremitting efforts to improve product quality, continuous and stable supply, and improve customer satisfaction. .

The "KPM" brand of Kawasaki Precision Machinery Co., Ltd. has an overwhelming market share in the field of construction machinery, especially hydraulic excavators, and continues to be active from Japan to Japan with its outstanding quality and performance. On the world stage of Europe, America and Asia, we continue to win the trust and greater expectations of the world.

Why does the hydraulic pump appear high temperature and the water temperature is normal?

1. The heat dissipation efficiency of the radiator is low.

If the tube-fin radiator is replaced with a plate-fin radiator, the heat dissipation area can be increased by 8m2, and the temperature difference between the inlet and outlet of the radiator can be increased from 7℃ to 10℃, and the effect is very obvious.

2. The air duct arrangement of the engine is unreasonable.

3. The one-way valve on the hot return oil circuit fails.

The oil return back pressure of the existing system is 0.3MPa, and the protection pressure of the oil cooler is 0.2MPa. It stands to reason that the oil return back pressure should be as low as possible while meeting the system back pressure requirements. The engine's oil temperature is too high, which may be: the resistance of the radiator is greater than the protection pressure, so that the hot oil in the oil return path is directly returned to the tank without passing through the radiator; the cleanliness of the system is poor, the check valve is stuck by dirt, and the valve core is In the normally open position, the radiator does not work; the opening pressure of the one-way valve cannot be guaranteed. Under the premise of meeting the system back pressure, the check valve of 0.30MPa can be changed to a check valve of 0.15MPa, and the protection pressure of the oil cooler can be increased to 0.35MPa.

In the hydraulic system. Hydraulic fluid is the working medium that transmits power and signals. At the same time, it also plays a role of lubrication, cooling and rust prevention. Whether the hydraulic system can operate effectively and reliably. To a large extent depends on the system The performance of the hydraulic fluid used in the hydraulic system. Therefore, before mastering the hydraulic system, you must have a clear understanding of the hydraulic fluid. In the hydraulic system, the hydraulic oil should have the following requirements:

1. Appropriate viscosity. Little change with temperature

The viscosity of the working medium is too large. The pressure loss of the system is large. The efficiency is reduced. Moreover, the oil absorption of the pump deteriorates, which is prone to cavitation and cavitation. It makes the pump operation difficult.

The viscosity of the working medium is too small, the system leaks too much, the volume loss increases, the system efficiency is also low, and the rigidity of the system becomes worse. In addition, the season changes. The temperature of the working medium will change before and after the machine is started and during normal operation. Therefore, in order to make the hydraulic system work normally and stably, the viscosity of the working medium is required to change with temperature to be small.

For Pumps, there are different kinds of brands, such as Kawasaki, Rexoth, Komatsu, Linde, Eaton, Parker, Kayaba, HAVE, SUER, UCHIDA,NACHI, JEIL, TEIJIN SEIKI, TOSHIBA, YUKEN, ITALY SAM, DAKIN, ITALY SAM, DENISON, OILGEAR, AND SO ON. Take Kawasaki for example,there are Model K3V112 Series, K3V140 Series, K3V180 Series, K3V280 Series, K5V140 Series, K5V160 Series, K5V200 Series and so on, if you are interested in hydraulic pump assemble or pump spare parts, pls feel free to contact our WONEPART spare parts center www.wonepart.com or email info@Wonepart.com or whatsapp:+86-15860751932, we will feel free to support you at any time.