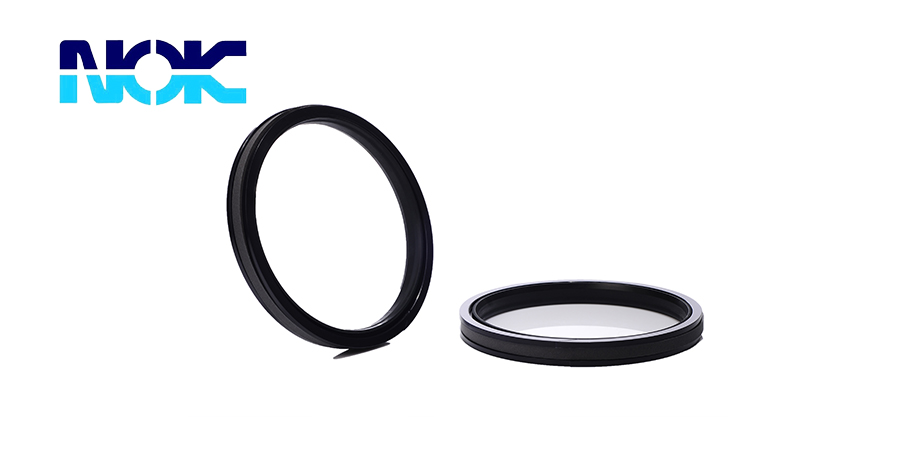

DKBI DUST SEAL

What is the service life of hydraulic seal? How to keep the construction machine seal like cylinder seal?

First,The working life of seal-hydraulic seal, cylinder seal, piston seal, rod seal, back-up ring, o ring

1.The condition of usage

A.Choosing the suitable materials, then you should pay attention to the material's adaptability to the working temperature and compatibility with the oil.

B.The material of the seal relative to the moving parts and the machining accuracy of the surface have an effect on the seal. The surface roughness value of the relatively moving surface is small, which has a good effect on prolonging the service life.

C.The lubrication state should be good.

D.To prevent dust and sand from entering.

E.The quality of the lubricating oil should be clean.

2.The service life of the seal depends on its operating conditions and environmental conditions.

At any stage during the use of the seal. The working conditions, including both during exercise and at rest, must be adapted to the selected conditions. Seals made of polyurethane rubber, for example, are afraid of oil containing water. If water is encountered, it will deteriorate and be inelastic. Another example is a seal made of NBR oil resistant rubber. When the oil temperature exceeds the allowable range, the oil temperature rises by 15 ° C and its life is reduced by 50%.

A.The seal used in the short stroke mechanism or hydraulic component can be calculated according to the number of actions, generally 15 to 250,000 times.

B.The seals used in long-stroke hydraulic cylinders can be calculated according to the mileage of the movement, generally 100 to 1500 km.

C.Seals for static sealing can be calculated according to the actual use time, generally 1.5 to 20,000 h or 1.5 to 2 years.

Second, seal storage

The seal is a consumable part and usually requires spare parts.

1.Control the retention period

Rubber seals are prone to natural ageing.

The actual service life of rubber seals should be equal to the sum of the storage period and the working period. To extend the service life, it is necessary to shorten the storage period between manufacture and use, and it is necessary to control the seals into and out of the warehouse. Only in this way can the seal be used to its fullest effect.

2.Keep the following points for custody.

A.Seals should be kept away from high room temperature, direct sunlight, humidity and air convection.

B.Seals are not allowed to be stacked or suspended to avoid permanent deformation.

C.The date of manufacture of the seal is recorded on the package and is issued for use within the storage period.

D.Put the seal in a polyethylene bag and seal it in a cool place.

E.The storage period is one year. Seals that exceed the storage period shall be inspected and treated, and those that do not meet the quality requirements shall be scrapped.