- NOK

- Japan

- 10 days

- 100000 pcs

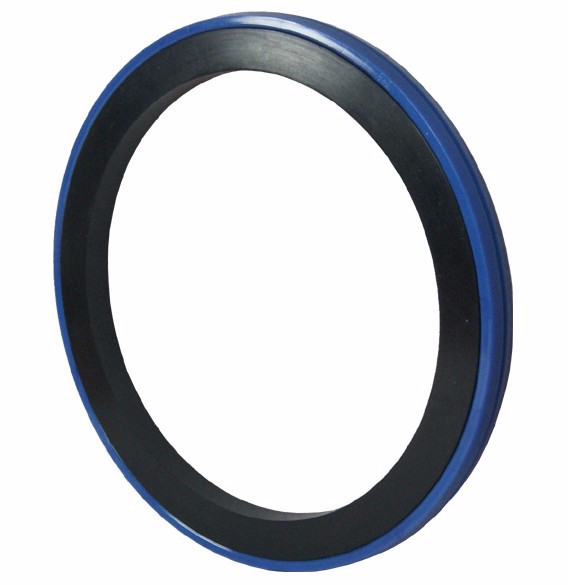

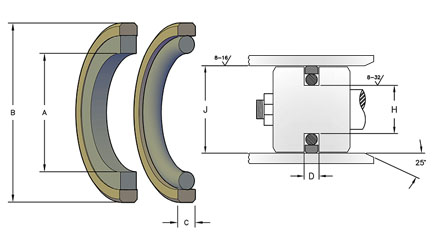

Piston seals maintain sealing contact in sliding motion between the piston and cylinder bore for hydraulic and pneumatic equipment.

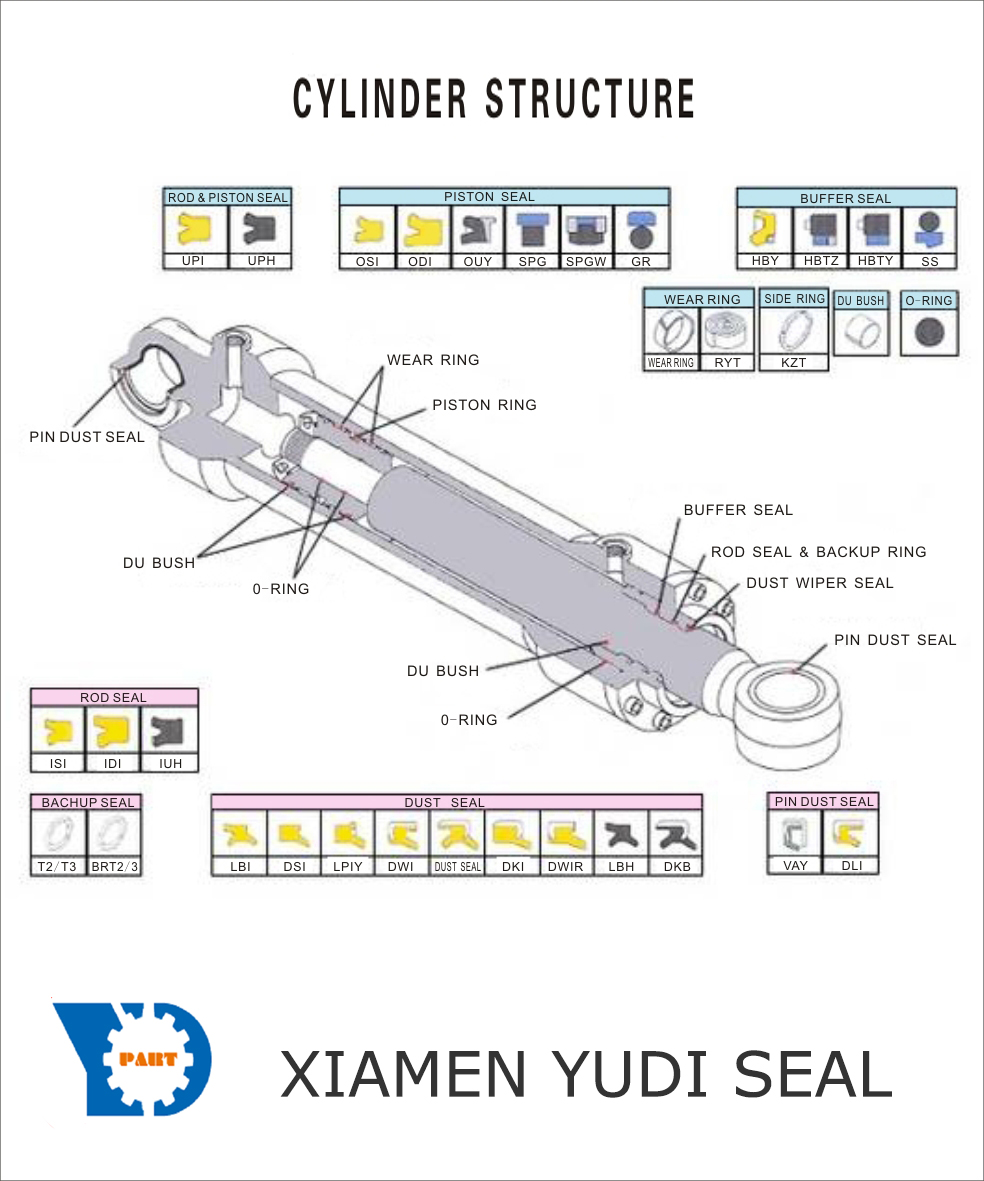

The piston seal is a shaft seal, and the piston rod seal is a hole seal. The oil cylinder is composed of a cylinder block, a piston, a piston rod, a cylinder head and a sealing ring. When using a piston seal, it can be used in combination with an anti-pollution seal to prevent damage due to foreign matter or adiabatic compression, which can improve durability. Types as following: ODI,OSI,OUIS,OUHR,OKH,SPGO,SPG,SPGM,SPGN,SPGW,SPGC,CPI,CPH

PISTON SEAL

The piston seal is a shaft seal, and the piston rod seal is a hole seal. The oil cylinder is composed of a cylinder block, a piston, a piston rod, a cylinder head and a sealing ring. When using a piston seal, it can be used in combination with an anti-pollution seal to prevent damage due to foreign matter or adiabatic compression, which can improve durability.

Piston seal maintain sealing contact in sliding motion between the piston and cylinder bore for hydraulic and pneumatic equipment.

If you want NOK brand piston seal, there are the types as following: ODI,OSI,OUIS,OUHR,OKH,SPGO,SPG,SPGM,SPGN,SPGW,SPGC,CPI,CPH

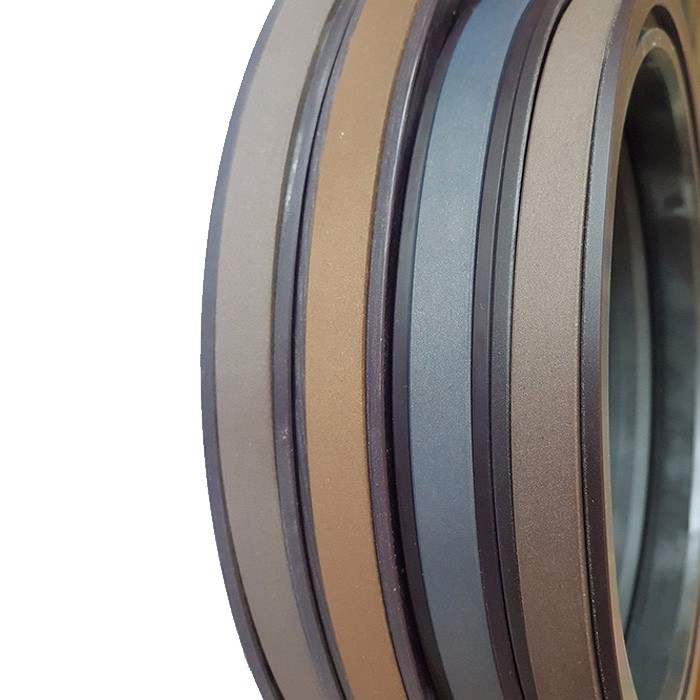

Material:PTFE+Rubber+Nylon or PTFE+Rubber;

Color: As per customer request if you have large quantities;

Piston seal assembly process

I. Assembly of piston seals (Assembly of Ф80 piston, Φ360 small plunger, and bottom seal of the cylinder ---- the seal assembly needs to pass through the guide ring groove)

1. Inspection: ① Make sure that the piston (small plunger, bottom of middle cylinder) is completely clean before assembly. Check for burrs, rough or sharp edges, erosion points, plating defects, etc.

② The seals must be matched and all parts must be clean and in good condition without defects such as aging, undercuts, indentations, scratches, etc.

2. Evenly lubricate the groove of the piston seal and the rubber part of the seal kit. A: Put a special tire on the edge of the piston seal groove 1-3mm, and push a part of the rubber ring into the tire. B: Gently stretch the exposed part into the tire. Then push it into the sealing groove as a whole in the axial direction to ensure that the rubber ring is fully in place. It is strictly prohibited to use sharp tools.

3. Install the anti-extrusion ring to the end of the piston near the piston rod. Do not try to overextend the ring to a "C" shape. (Slightly screw the rest into the groove, making sure it is properly seated in the stepped groove of the rubber ring).

4. Install the gray sealed outer surface. Apply a thin layer of lubricant to the grey seal outer surface and the leading edge of the special tire. Push a part of the gray outer surface into the mold. Gently stretch the exposed part into the tire. Then push it into the sealing groove as a whole in the axial direction to ensure that the gray outer surface is all in place. Never use sharp tools.

5. Install the second anti-extrusion ring. Pull the ring apart in the axial direction of the ring, put one end into the sealing groove, and gently screw the rest into the groove. Do not use sharp tools.

6. Gently open the guide ring, and then slide it over the sealing surface of the piston, and the guide ring will "snap" into its own groove on the piston. Before installation, lightly squeeze the ends of the guide ring to make them overlap. Rotate the anti-extrusion ring so that the two cutouts are approximately 180 degrees.

2. Assembly of piston seals (Ф63, Φ125, Φ160, Φ165, Φ200 piston seal assembly)

1. Inspection: ① Make sure that the piston is completely clean before assembly. Check for burrs, rough or sharp edges, erosion points, plating defects, etc. ② The seals shall be matched and all parts shall be clean and in good condition, and there shall be no defects such as aging, undercuts, indentations, scratches, etc.

2, evenly lubricate the groove of the piston seal and the rubber part of the seal kit. A: Put a part of the rubber ring into the groove. B: Gently stretch the exposed part into the groove along the assembly chamfer to ensure that the rubber ring is fully in place.

Never use sharp tools.

3. Install the anti-extrusion ring to the end of the piston near the piston rod. Do not try to open the ring to a "C" shape. (Pull the ring apart in the axial direction of the ring, put one end into the sealed groove, and gently screw the rest into the groove to ensure that it is correctly located in the stepped groove of the rubber ring)

4. Install the gray sealed outer surface. Apply a thin layer of lubricant to the gray seal outer surface and the leading edge of the piston. Push a part of the gray outer surface into the groove, located on the rubber ring, and gently put the exposed part into the groove to ensure that the gray outer surface is all in place. Never use sharp tools.

5. Install the second anti-extrusion ring. Pull the ring apart in the axial direction of the ring, put one end into the sealing groove, and gently screw the rest into the groove. Do not use sharp tools.

6. After the groove of the Ф63 piston guide ring is oiled, gently open the guide ring, and then slide it over the sealing surface of the piston. The guide ring will "snap" into its own groove on the piston. Press the ends of the guide ring notch so that they overlap. Rotate the anti-extrusion ring so that the two cutouts are approximately 180 degrees.

7. After Φ125, Φ160, Φ165, Φ200 piston and piston rod are assembled, after adding anti-loosening and tightening the fastening screw, the piston guide ring groove is oiled and then the guide ring is installed. Before the whole assembly, lightly squeeze the two ends of the guide ring cut so that they overlap, and then rotate the anti-extrusion ring so that the two cuts are about 180 degrees.

The problems existing in piston sealing mechanism, separating oil from water recovery of floating oil etc.

If you want other Chinese manufacture piston seal, you could feel free to contact us by email info@wonepart or whatsapp:+86-15860751932. Our sales team and engineer team will support you at any time.