- NOK

- Japan

- 10 days

- 100000 pcs

The oil seal is a typical representative of the oil seal. Generally speaking, the oil seal refers to the oil seal. The skeleton is like the reinforcing steel in the concrete component, which strengthens and keeps the oil seal in shape and tension. According to the structure, it can be divided into single-lip oil seal and double-lip oil seal. Frame oil seal type TC, TC3, TB, HTC, HTC3, HTC5, HTC9, TCL, SCY, SCJY, VSB, VSB2, HTBW, HSC, TA, SA, SB, SC, CAP4, TCN, TCV, DKB, HTCL, EC, TBV, TG4.

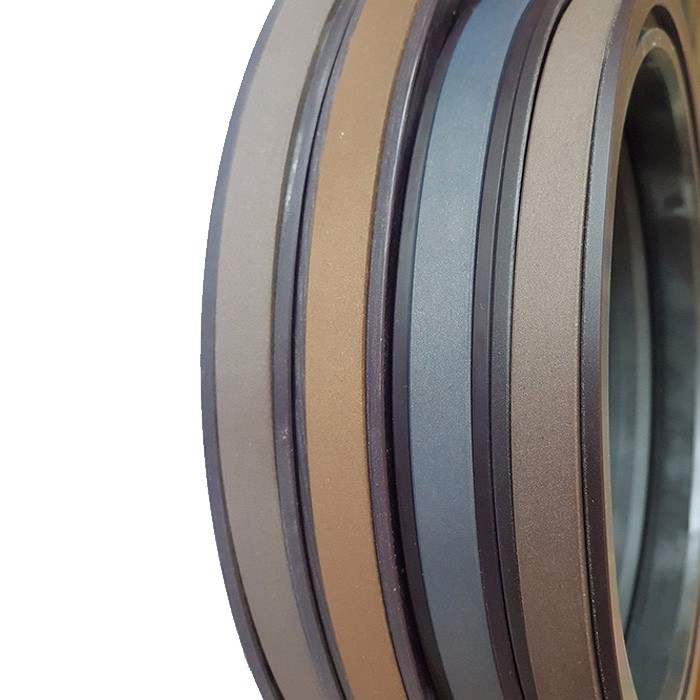

OIL SEAL

The oil seal is a typical representative of the oil seal. Generally speaking, the oil seal refers to the oil seal. The role of the oil seal is generally to isolate the components in the transmission component that need to be lubricated from the external environment, so as not to allow the lubricant to leak. The skeleton is like the reinforcing steel in the concrete component, which strengthens and keeps the oil seal in shape and tension. According to the structure, it can be divided into single-lip oil seal and double-lip oil seal. The secondary lips of the double-lip oil seal play a dust-proof role to prevent outside dust, impurities, etc. from entering the inside of the machine. According to the skeleton type, it can be divided into inner oil seal, exposed oil seal and assembled oil seal. According to working conditions, it can be divided into rotary oil seal and reciprocating oil seal. Used in crankshafts of gasoline engines, crankshafts of diesel engines, gearboxes, differentials, shock absorbers, engines, axles and other parts.

Oil seal structure

The oil seal structure consists of three parts: oil seal body, reinforced skeleton and self-tightening coil spring. The sealing body is further divided into a bottom part, a waist part, a cutting edge and a sealing lip according to different parts. Generally, the oil seal in the free state has a smaller inner diameter than the shaft diameter, that is, it has a certain "interference".

Therefore, after the oil is sealed into the oil seal seat and the shaft, the pressure of the oil seal edge and the contraction force of the self-tightening coil spring generate a certain radial tight force on the shaft. After a period of operation, the pressure will quickly decrease or even disappear Therefore, the spring can compensate the oil seal self-tightening force at any time.

Framework oil seal sealing principle

Sealing principle: Because there is an oil film controlled by the oil seal edge between the oil seal and the shaft, this oil film has fluid lubrication characteristics. Surface tension in liquid

oil seal

Under the action of the oil film, the rigidity of the oil film just makes a crescent surface between the oil film and the air contact end, preventing the leakage of the working medium, thereby achieving the sealing of the rotating shaft. The sealing ability of the oil seal depends on the thickness of the oil film on the sealing surface. If the thickness is too large, the oil seal leaks; if the thickness is too small, dry friction may occur, causing oil seal and shaft wear; if there is no oil film between the seal lip and the shaft, it is easy to cause heat and wear. .

Therefore, during installation, you must apply some oil to the seal ring, and at the same time ensure that the oil seal is perpendicular to the axis of the shaft. If it is not vertical, the seal lip of the oil seal will drain the lubricant from the shaft, and it will also cause excessive seal lip. abrasion. During operation, the lubricant in the housing slightly oozes out, so that it is ideal to form an oil film on the sealing surface.

The function of the oil seal is generally to isolate the parts that need to be lubricated from the output parts in the transmission parts, so as not to allow the lubricant to leak. It is usually used for

The rotary shaft is a rotary shaft lip seal. The skeleton is like the reinforcing steel in the concrete component, which strengthens and keeps the oil seal in shape and tension. According to the skeleton type, it can be divided into inner oil seal, outer oil seal, and inner and outer oil seal. The oil seal is made of high-quality nitrile rubber and steel plate, with stable quality and long service life. Widely used in automobile, motorcycle crankshaft, camshaft, differential, shock absorber, engine, axle, front and rear wheels and other parts.

1. Prevent mud, sand, dust, water and gas from entering the bearing from the outside;

2. Limit the leakage of lubricant in the bearings. The requirements for oil seals are that the size (inner diameter, outer diameter and thickness) should meet the requirements; proper elasticity is required to properly hold the shaft to play a sealing role; heat resistance, wear resistance, good strength, and resistance to media Oil or water), long life.

Reasonable use of oil seals should pay attention to the following points:

(1) Shaft speed Due to design and structural reasons, high-speed shafts should use high-speed oil seals, low-speed shafts use low-speed oil seals, and low-speed oil seals cannot be used on high-speed shafts, and vice versa.

(2) Ambient temperature In the case of high use temperature, polypropylene ester or silicon, fluorine, silicon fluorine rubber should be selected. And try to reduce the oil temperature in the fuel tank. When the operating temperature is too low, cold-resistant rubber should be used.

(3) Oil seals with normal pressure can withstand poor pressure. When the pressure is too large, the oil seal will deform. Under the conditions of excessive pressure, a pressure-resistant support ring or a reinforced pressure-resistant oil seal should be used.

(4) Degree of eccentricity during installation When the oil seal is too eccentric with the shaft, its sealing performance will be worsened, especially when the shaft speed is high. If the eccentricity is too large, an oil seal with a "W" cross section can be used.

(5) The surface smoothness of the shaft directly affects the service life of the oil seal, that is, if the smoothness of the shaft is high, the service life of the oil seal will be long.

(6) Note that there should be a certain amount of lubricating oil on the lips of the oil seal.

(7) Pay special attention to prevent dust from getting into the oil seal.

The existence of "critical oil film" at the edge of the oil seal is very beneficial to reduce the wear of the oil seal edge and increase the life of the oil seal. Especially when several oil seals are used in parallel, special attention should be paid to the supply of lubricant (grease). Otherwise, Dry friction will be formed due to lack of oil, which will cause the oil seal to burn out. Generally, lithium-based grease is the best choice. In order to ensure the cleanliness of the grease and the timely removal of impurities or other harmful impurities accumulated in the grease, it is important to replace the grease regularly. Therefore, in terms of structural design, there must be oil injection holes and oil drainage holes. In order to prevent the temperature of the oil seal sealing cavity from rising, it is sometimes important to open a vent hole.

Tips for oil seal

1. Obtain a fixed number of oil seals.

2. It must be kept clean from oil seal collection to assembly.

3. Before assembly, check the oil seal and measure whether the dimensions of the frame oil seal are consistent with the dimensions of the shaft and cavity. Before installing the frame oil seal, compare the diameter of the shaft diameter with the inner diameter of the oil seal. The internal size of the cavity should be suitable for the outer diameter of the oil seal. Check whether the lips of the oil seal are damaged or deformed, and whether the spring is detached or rusted. Prevent the oil seal from laying flat during transportation, and be affected by external forces such as squeezing and impact, and damage its roundness.

4. Do machining inspection procedures before assembly, and measure whether the dimensions of the cavity and the shaft are correct, especially the internal chamfers, no slope, and the end faces of the shaft and cavity should be smooth, without chamfers and burrs, clean. For assembly parts, there should be no burrs, sand, iron filings and other debris in the shaft mounting (chamfering) part, which will cause irregular damage to the oil seal lip. It is recommended that the chamfering part adopt the r angle.

5. In the operation skills, you can feel it by hand, whether it is smooth and round.

6. Don't tear the packaging paper too early before installing the oil seal to prevent debris from adhering to the surface of the oil seal and bringing it into work.

7. Prior to installation, the oil seal should be smeared with a lithium ester with molybdenum disulfide added between the lips in order to prevent the shaft from dry-running when the shaft starts instantly, which will affect the interference of the lips. It should be assembled as soon as possible. If the oil seal seat of the oil seal is installed, if it is not installed immediately, it is recommended to cover it with a cloth to prevent foreign matter from attaching to the oil seal. Lithium-coated hands or tools must be clean.

8. oil seals must be installed flat, without tilting. It is recommended to use hydraulic equipment or socket tools for installation. The pressure should not be too great, the speed should be uniform and slow.

9. Mark the machine for the framework oil seal installed this time to facilitate tracking and pay attention to the entire process.

Frame oil seal type

TC, TC3, TB, HTC, HTC3, HTC5, HTC9, TCL, SCY, SCJY, VSB, VSB2, HTBW, HSC

TA, SA, SB, SC, CAP4, TCN, TCV, DKB, HTCL, EC, TBV, TG4

If you are looking for all types of oil seal ,pls feel free to contact us by email info@wonepart.com or whatsapp:+86-15860751932.