High Quality Hydraulic Pump Valve Quotes and Working Principle

The working principle of various electromagnetic reversing valves makes you a hydraulic master

Dynamic diagram demonstration of the working principle of hydraulic valve, let you understand instantly!

Hydraulic valve is an automatic component operated with pressure oil, but how does it work? What's the use? After carefully reading these 20 visual animations, you will understand! First of all, we need to know the types of hydraulic valves: Classification by control method: manual, electronic, hydraulic; Classification by function: flow valve (throttle valve, speed control valve, diverter manifold), pressure valve (overflow Valve, pressure reducing valve, sequence valve, unloading valve), directional valve (electromagnetic directional valve, manual directional valve, check valve, hydraulic control check valve); Classification by installation method: plate valve, tube valve, Superimposed valve, threaded cartridge valve, cover valve; classified by operating method: manual valve, motorized valve, electric valve, hydraulic valve, electro-hydraulic valve, etc. 1.Manual directional valve

Hydraulic valve is an automatic component operated by pressure oil. It is controlled by pressure oil of pressure regulating valve. It is usually used in combination with electromagnetic pressure regulating valve and can be used to remotely control the on-off of oil, gas and water pipeline systems of hydropower stations. Today, Xiaoqi equipped everyone with a moving picture to introduce the principles and functions of various hydraulic valves!

Classification by control method: manual, electric, hydraulic

Classified by function: flow valve (throttle valve, speed regulating valve, diverter manifold), pressure valve (overflow valve, pressure reducing valve, sequence valve, unloading valve), directional valve (solenoid valve, manual valve Check valve, check valve, hydraulic control check valve)

◆ ◆ ◆

Check valve

One-way valve is that the fluid can only flow along the water inlet, but the medium at the water outlet cannot return. It is commonly known as one-way valve. Check valve is also called check valve or check valve. Used to prevent reverse flow of oil flow in hydraulic systems, or to prevent reverse flow of compressed air in pneumatic systems.

When installing the check valve, special attention should be paid to the flow direction of the medium, and the normal flow direction of the medium should be consistent with the direction of the arrow indicated on the valve body, otherwise the normal flow of the medium will be blocked. The foot valve should be installed at the bottom of the suction pipe of the pump.

When the check valve is closed, water hammer pressure will be generated in the pipeline. In serious cases, it will cause damage to the valve, pipeline or equipment, especially for large-mouth pipelines or high-pressure pipelines. .

Right Angle Check Valve

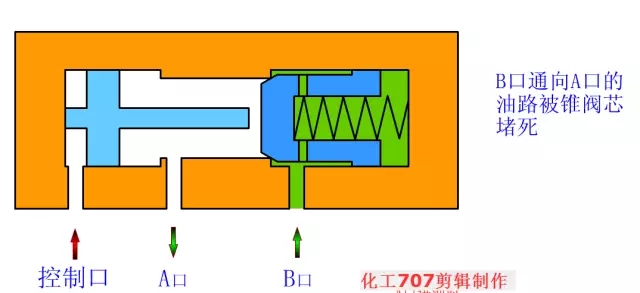

Directional check valve

When check valve A inlet oil

When check valve B inlet oil

Non-return valve with control oil

Directional valve

Directional valves are directional control valves with two or more flow patterns and two or more ports. It is a valve that realizes the communication, cut-off and reversal of hydraulic oil flow, as well as pressure unloading and sequential action control.

This shift valve has a wide range of applications in petroleum and chemical production, and is most commonly used in synthetic ammonia gas production systems. In addition, the reversing valve can also be made into a disc structure, which is mostly used in small flow situations. When working, just turn the hand wheel through the valve flap to change the flow direction of the working fluid.

◆ ◆ ◆

Directional valve-two-position two-way

Two-position means that the valve core works in two states. When the coil is not energized, the valve core is in one position, and when it is energized, it moves to another position. The position of the valve is switched by changing the position. Two interfaces (one in and one out).

The two-position two-way valve is actually a shut-off valve. It has the purpose of closing / opening the pipeline and has no reversing function.

◆ ◆ ◆

◆ ◆ ◆

Directional valve-two-position four-way

The two-position four-way reversing valve is suitable for dry oil or thin oil centralized lubrication system to switch the oil supply direction or open and close the oil supply pipeline.

This reversing valve uses a high-torque DC geared motor to drive the reversing, so the reversing action is very reliable even under severe working conditions (such as low temperature or high viscosity grease). During the commutation process, the piston runs at a higher speed in a very short time, reducing reciprocation, thereby avoiding premature wear.

After receiving the commutation signal in the system, the DC motor makes a rotary motion, and the rotary motion is converted into a linear reciprocating motion of the piston rod by an eccentric wheel. When the piston moves from one end to the other end and reaches the required commutation position, the limit switch operates, causing the DC motor to lose power, and then the motor stops rotating, and the commutation process is completed.

Directional valve-two-position four-way

Directional valve-two-position four-way

Directional valve-two-position four-way

◆ ◆ ◆

Directional valve-three-position four-way

P is the oil supply port, O is the oil return port, and A and B are the output ports to the actuator.

When the spool is in the neutral position, all ports are shut off and the actuator is not moving;

When the spool moves to the right position, P is connected to A, B is connected to O;

When the spool moves to the left position, P and B pass, and A and O pass.

In this way, the actuator can move forward and backward.

Directional valve-three-position four-way

◆ ◆ ◆

Directional valve-three-position five-way

Directional valve-three-position five-way left

Directional valve-three-position five-way

Directional valve-three-position five-way

◆ ◆ ◆

Manual Directional Valve

The manual directional valve is a directional control valve that relies on the force of a manual lever to drive the valve core to realize the on / off or switching of the oil circuit.

The manual directional valve plays the same role in the hydraulic system as the electromagnetic directional valve. Simple operation, reliable work, and no power required.