- NOK

- Japan

- 10 days

- 100000 pcs

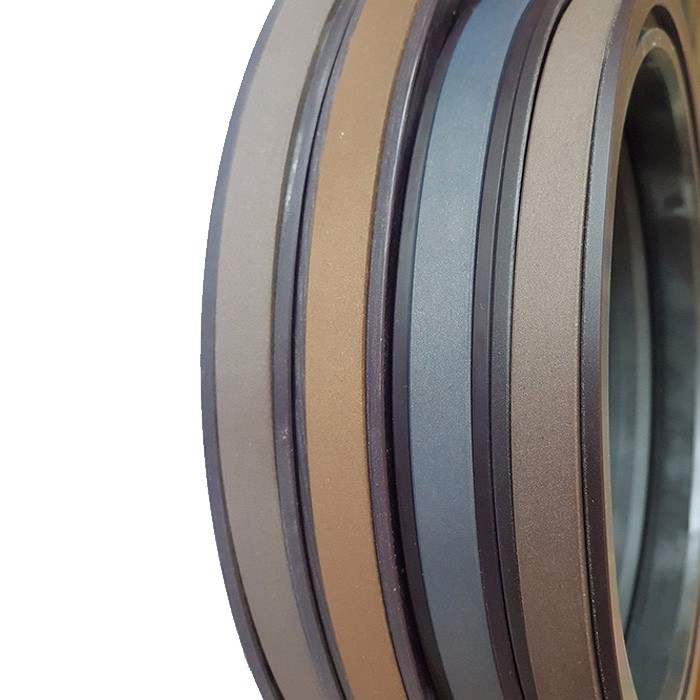

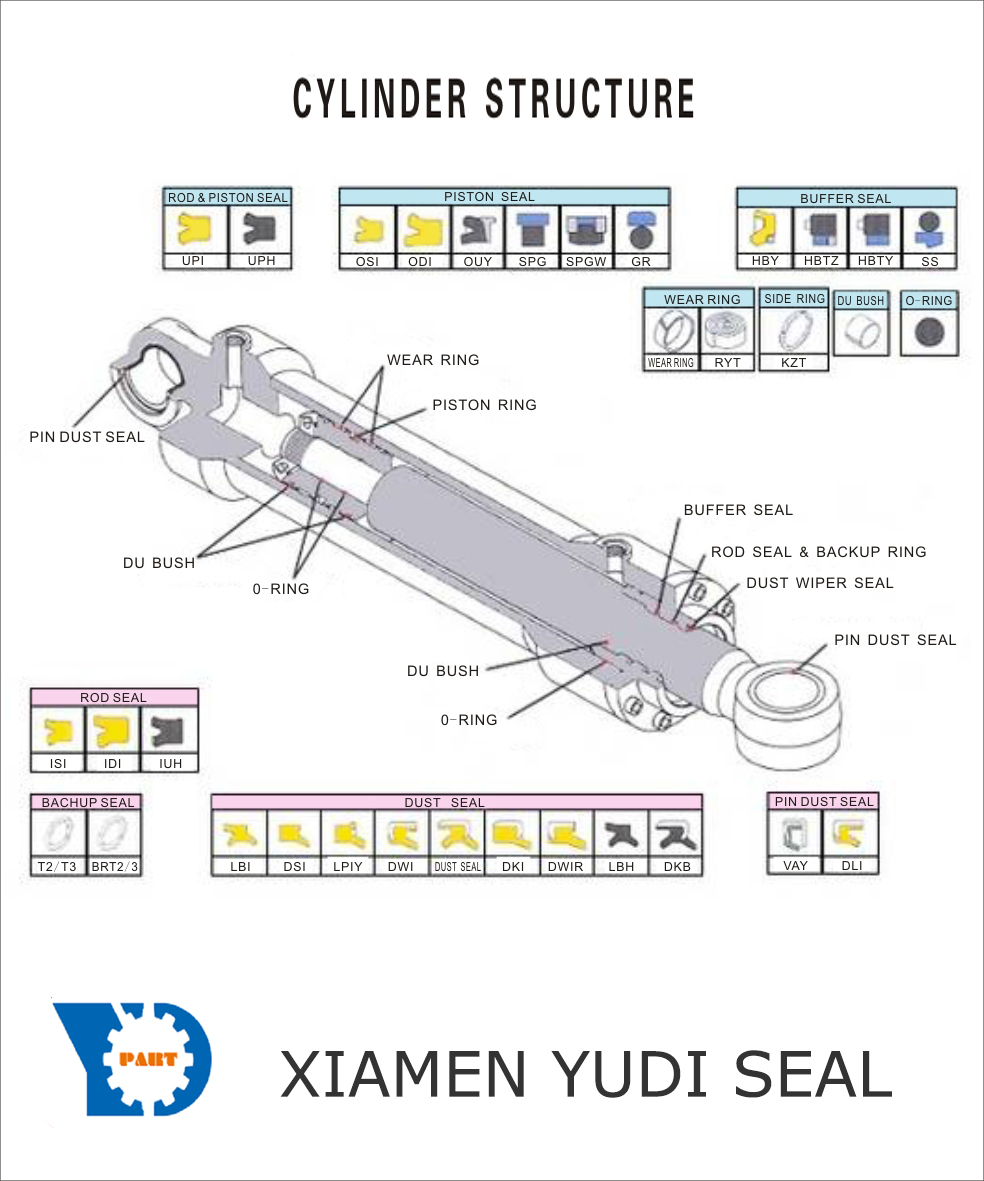

Wear ring or guide ring is used as bearing of rod and piston to prevent its scoring or accentricity and to improve the durability of the packing.For high speed, low load, or creeping, please use polytetrafluoroethylene resin model RYT or RYT2 with excellent friction and abrasion characteristics.The material of RYT is polytetrafluoroethylene resin, which is characterized by a low friction and wear ring without creeping. We calculate by volume and can cut according to the size of the cylinder bore. Can withstand temperatures ranging from -55 degrees Celsius to 220 degrees Celsius.

WEAR RING

Wear ring or guide ring is used as bearing of rod and piston to prevent its scoring or accentricity and to improve the durability of the packing.

Wear ring effect

The wear ring is used as a supporting element on the piston to prevent the piston and the cylinder from scratching each other, reduce the eccentricity, and improve the durability of the seal.

Selection of wear ring

The shape and material of the wear ring should be selected according to the working conditions. Like the oil cylinders for construction equipment, at low speeds and high loads, phenolic resin and WR containing resin fibers are used. For high speed, low load, or creeping, please use polytetrafluoroethylene resin model RYT or RYT2 with excellent friction and abrasion characteristics.

The material of RYT is polytetrafluoroethylene resin, which is characterized by a low friction and wear ring without creeping. Excellent wear resistance in high speed and low load areas. We calculate by volume and can cut according to the size of the cylinder bore. Can withstand temperatures ranging from -55 degrees Celsius to 220 degrees Celsius.

The material of WRT2 is polytetrafluoroethylene resin, which is characterized by a low friction and wear ring that does not creep. Excellent wear resistance in high speed and low load areas. It has a beveled cut and we can produce your desired diameter and width according to your requirements. Can withstand temperatures ranging from -55 degrees Celsius to 220 degrees Celsius.

The material of WR contains polyester of resin fiber, which has excellent impact strength and strong lateral load wear ring. Both pistons and rods can be used together. There is a chamfered buckle, we can produce your desired diameter and width products according to your requirements. Can withstand temperatures ranging from -60 degrees Celsius to 130 degrees Celsius.

If the size of the mounting groove is the same, it can be used in combination with the inner diameter cutting of the oil cylinder, so it is not necessary to prepare a wear ring separately for each size of the oil cylinder.

Based on NOK standard, wear ring including WR,KZT,RYT

Material: Phenol(Carbon30%)

Color: As per customer request if you have large quantities;

How to assemble the wear ring or guide ring

1. Inspection: ① Make sure that the guide sleeve is completely clean before assembly. Inspection: Burrs, rough or sharp edges, erosion points, plating defects, etc. ② The seals shall be matched and all parts shall be clean and in good condition, and there shall be no defects such as aging, undercuts, indentations, scratches, etc.

2. Lubricate all parts of the inner diameter of the guide sleeve evenly. Pay special attention to the groove where the rod dust ring is located.

3. Make sure that the rod seal is in the correct direction, and the stepped part of the assembly pressure-resistant ring should face the upper part of the end cover of the guide sleeve. Put a part of the seal into the groove first. Then gently tuck the rest into the groove, or twist the seal into the shape of a kidney and then tuck into the groove. Make sure the seals are in place and do not use sharp tools.

4. Install anti-extrusion ring. Place a part of the anti-extrusion ring into the stepped groove of the rod seal, and then gently plug the rest into the rod seal. Ensure that the anti-extrusion ring is properly seated. Don't use sharp tools

5. Lubricate the groove of the static seal of the guide sleeve evenly. The "Y" opening of the static seal faces the end of the cylinder bottom. Then push a part of the static seal into the groove, and then gently extend the exposed part into In the groove, make sure that all seals are in place. Never use sharp tools!

6. After the groove of the guide ring is oiled, put the guide ring into the groove gently, and rotate the guide ring to make the two cutouts approximately 180 degrees.

7. The upper part of the end cover of the guide sleeve is facing up. After the groove of the dust ring is lubricated, put a part of the dust ring into the groove first. Then gently tuck the rest into the groove, or twist the dust wiper into the shape of a kidney, then tuck into the groove. Make sure the dust wiper is properly seated. Do not use sharp tools.

For guide ring or wear ring, there are many types, different types have different function, it depends on the location and function that you need, then we will find the best solution to you.As we are professional in manufacturing for all kinds of wear ring or guide ring.

Touch me, if you are interested in our products.

Email: info@wonepart.com, Whatsapp: +86-15860751932