New excavators machinery to rebuild new economy and recovery after corona virus pandemic

New excavators machinery to rebuild new economy and recovery after corona virus pandemic

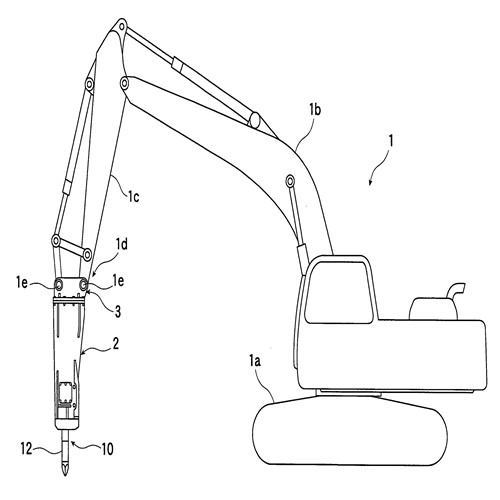

Excavating machinery, also known as excavator, is an earth-moving machine that uses a bucket to excavate materials above or below the bearing surface and load it into a transport vehicle or unload it to a stockyard. The materials excavated by the excavator are mainly soil, coal, silt and soil and rocks after pre-loose. From the perspective of the development of construction machinery in recent years, the development of excavators is relatively fast, and excavators have become one of the most important construction machinery in engineering construction. The three most important parameters of an excavator: operating weight (mass), engine power and bucket capacity.

Excavator, invented in the 1870s, according to the driving mode, divided into internal combustion-driven excavators and electric-driven excavators. According to the walking mode, they were divided into crawler excavators and wheeled excavators. According to the transmission mode, they were divided into hydraulic excavators and machinery. Excavators are divided into shovel excavators, backhoe excavators, alias excavators, excavators, and backhoe excavators according to the bucket.

Excavator development history

In the beginning, the excavator was manual. It has been more than 130 years since it was invented in 2013. During this period, it has experienced a complete range from steam-driven bucket rotary excavators to electric and internal combustion engine driven rotary excavators, and the application of electro mechanical-hydraulic integration technology. The gradual development process of automatic hydraulic excavators. The first hydraulic excavator was successfully invented by the Poclain factory in France. Due to the application of hydraulic technology, a hydraulic backhoe mounted excavator was installed on the tractor in the 1940s. In 1951, the first fully hydraulic backhoe excavator was launched by the Poclain factory in France, thus creating a new space in the field of excavator technology development. In the early and mid-1950s, the trailer was developed successively. Full-rotation hydraulic excavator and crawler full hydraulic excavator. The initial trial-produced hydraulic excavators used the hydraulic technology of airplanes and machine tools, and lacked hydraulic components suitable for various working conditions of the excavators, the manufacturing quality was not stable enough, and the supporting parts were not complete. Since the 1960s, hydraulic excavators have entered a stage of promotion and vigorous development. Excavator manufacturers and varieties in various countries have increased rapidly, and output has soared. From 1968 to 1970, the output of hydraulic excavators accounted for 83% of the total output of excavators, which was close to 100% .

The first generation of excavators: the emergence of electric motors and internal combustion engines gave excavators advanced and suitable electric devices, so various excavator products were born. In 1899, the first electric excavator appeared. After the First World War, diesel engines were also used in excavators. This diesel engine (or electric motor) driven mechanical excavator was the first generation of excavators.

Second-generation excavators: With the widespread use of hydraulic technology, excavators have more scientific and applicable transmission devices. Hydraulic transmission instead of mechanical transmission is a great leap in excavator technology. In 1950, Germany's first hydraulic excavator was born. Mechanical transmission hydraulic is the second generation excavator.

The third-generation excavator: The wide application of electronic technology, especially computer technology, has enabled the excavator to have an automated control system, and also enabled the excavator to develop in the direction of high performance, automation and intelligence. The germination of mechanics took place around 1965, and the use of mechanics technology on mass-produced hydraulic excavators was around 1985. The main purpose at that time was to save energy. The electronic excavator is the symbol of the third-generation excavator.

Excavator manufacturers can be roughly divided into four categories. More than 70% of domestic excavators are occupied by foreign brands. Domestic brands are still dominated by small excavators and medium excavators, but the share of domestic excavators is gradually increasing, with a year-on-year increase of 3.6% in 2012.

Overview of Excavator Development

Excavator domestic

China's excavator production started relatively late. Since the Fushun Excavator Factory produced the first mechanical single-bucket excavator with a bucket capacity of 1m³ in 1954, it has generally gone through three stages of surveying and mapping imitation, independent research and development, and development improvement. .

In the early days of the founding of the People’s Republic of China, the former Soviet Union’s W501, W502, W1001, and W1002 mechanical single-bucket excavators were mainly surveyed and mapped from the 1930s to the 1940s, and the history of Chinese excavator production began. Due to the needs of the country's economic construction at that time, more than a dozen excavator production plants have been established. Since 1967, China has independently developed hydraulic excavators. The products successfully developed in the early stage mainly include WYl00 type from Shanghai Construction Machinery Plant, W4-60 type from Guiyang Mining Machinery Plant, WY60 type excavator from Hefei Mining Machinery Plant, etc. Then there appeared WYl60 type excavator from Changjiang Excavator Factory and WY250 type excavator from Hangzhou Heavy Machinery Factory. They have taken an extremely important step for the formation and development of China's hydraulic excavator industry.

By the end of the 1980s, there were more than 30 excavator manufacturers in China with more than 40 types of production models.

Since the reform and opening up, we have actively introduced, digested and absorbed foreign advanced technologies to promote the development of China's excavator industry. Due to the continuous increase and diversification of domestic demand for hydraulic excavators, the adjustment of the product structure of large and medium-sized state-owned enterprises has affected some other machinery industry manufacturers to join the hydraulic excavator industry.

Industry insiders pointed out that China’s single-bucket hydraulic excavators should be fully hydraulic; the bucket capacity should be controlled within 0.1-15 m³; and for large-scale and multi-bucket excavators, due to the high requirements for the manufacture and assembly of hydraulic components, site maintenance If the conditions are poor, the mechanical type is still the mainstay. Should start to study and apply electro-hydraulic control technology to realize the automation of hydraulic excavator operation.

my country began to research and develop excavator products in the late 1960s. After just over 40 years, especially over 30 years of reform and opening up, China's excavator manufacturing industry has developed particularly rapidly. According to data from the National Bureau of Statistics, in 2010, there were 252 enterprises above the designated size in the excavator manufacturing industry in China, achieving sales of 169.785 billion yuan, realizing product sales profits of 25.367 billion yuan, and total profits of 21.406 billion yuan, a year-on-year increase of more than 80%.

The Chinese excavator market is increasing at an average rate of 30%, making it one of the largest markets in the world. From the perspective of development, China is at the peak of infrastructure construction in various aspects such as road transportation, energy and water conservancy, and urban construction. The market demand for excavators is increasing year by year. In 2010, the actual cumulative sales of excavators nationwide exceeded 165,000. The year-on-year increase reached 74.5%.

At the end of 2010, major domestic companies have expanded their excavator production capacity, and other companies have opened up a series of excavator models in an attempt to drive corporate profit growth through the rapid growth of the excavator market. In fact, there are both risk factors and income considerations. Bank credit is not active in promoting the construction of affordable housing, which indirectly led to the decline in sales of construction machinery in the second quarter of 2011. In May 2011, domestic sales of excavators were 13,956 units, a year-on-year decrease of 12.4%, and for the first time in a single month, a year-on-year decline; cumulative sales from January to May were 115,589 units, a year-on-year increase of 38.1%, a decrease of 12 percentage points from January to April.

According to the data disclosed by Construction Machinery Online, as of September 2014, the sales volume of mini excavators under 6 tons totaled 1,006 units, of which foreign brands had a market share of 55.0% and domestic brands had a market share of 45.0%. In addition, the sales volume of excavators over 6 tons was 3139 units, the market share of foreign brands was 61.0%, and the market share of domestic brands was only 39.0%. According to information from Sany Heavy Industry, from 2011 to 2013, the company's domestic market share of excavators reached 11.56%, 15.8%, and 13.7%, respectively, surpassing Carter and ranked first in the industry. Its market share once again exceeded 15%. The industry believes that the company won the first place this year and it has no suspense to achieve the "four-year sales crown".

On the whole, the domestic inventory of excavators is low, but the product prices are relatively high. The sales model is mainly based on financial leasing or bank mortgage. Once credit is relaxed, excavator sales will be the best product to rebound. It can be predicted that from 2011 to 2013, as the world's Chinese economy recovers, real estate and urbanization are accelerated, the sales of excavators of various tonnages will also continue to grow. After deducting uncertain factors, the excavation of various tonnages in 2011-2013 The machine will grow at a growth rate of over 15%.

With the continuous intensification of competition in the excavator manufacturing industry, mergers and acquisitions and capital operations among large excavator manufacturing companies are becoming more frequent. Excellent excavator manufacturing companies in China are paying more and more attention to the research of the industry market, especially the industry development environment and products. In-depth study of buyers. It is precisely because of this that a large number of excellent domestic excavator brands have risen rapidly, and have gradually become leaders in the excavator manufacturing industry in China and the world!

Excavator abroad

It has been more than 130 years since the first manual excavator came out.

Excavators in industrially developed countries were produced earlier. France, Germany, the United States, Russia, Japan, etc. are the main producers of single-bucket hydraulic excavators with a bucket capacity of 3.5-40 m3. Super-large excavators have been produced since the 1980s. For example, the stripping excavator with a bucket capacity of 50-150 m3 produced by Marion Company of the United States, and a walking dragline excavator with a bucket capacity of 132 m3; and the bucket capacity of 168.2 m3 produced by BE (Busai Lusi Yili) The walking dragline excavator and the stripping excavator with a bucket capacity of 107 m3 are currently the largest excavators in the world.

Since the late 20th century, the production of excavators in the world has developed in the direction of large-scale, miniaturized, multi-functional, specialized and automated.

1) Develop excavators with multiple varieties, multiple functions, high quality and high efficiency. In order to meet the needs of municipal construction and farmland construction, foreign countries have developed mini excavators with a bucket capacity below 0.25 m3, and the smallest bucket capacity is only 0.01 m3. In addition, the largest number of medium and small excavators tend to have multiple functions and are equipped with a variety of working devices-in addition to front shovel and backhoe, they are also equipped with lifting, grab buckets, leveling buckets, loading buckets, and harrows. Teeth, broken cones, twist drills, electromagnetic chucks, vibrators, bulldozing plates, impact shovel, container forks, aerial work frames, reamers and draglines, etc., to meet various construction needs. At the same time, develop special excavators for special purposes, such as low specific pressure, low noise, underwater special and amphibious excavators.

2) The rapid development of full hydraulic excavators, continuous improvement and innovation of control methods, so that the excavator developed from simple lever control to hydraulic control, pneumatic control, hydraulic servo control and electrical control, radio remote control, electronic computer integrated program control. In dangerous areas or underwater operations, radio control is used, and the electronic computer control receiver is combined with laser guidance to realize the complete automation of excavator operation. All of this, the full hydraulic excavator has laid the foundation and created a good premise for it.

3) Attach importance to the adoption of new technologies, new processes, and new structures, and accelerate the development of standardization, serialization and generalization. For example, the excavator produced by Atlas Company of Germany is equipped with a new type of engine speed adjustment device, so that the excavator can work at the speed most suitable for its operation requirements.

We wonepart supply all kinds of brand of spare parts for komatsu, caterpillar, volvo, doosan, hitachi, sumitomo and so on, if you have enquiry for seal kits, pump parts, engine parts or the whole excavator machinery pls feel free to email us info@wonepart.com or whatsapp:+86-15860751932.