Three minutes to learn how to adjust the main relief valve when excavator is powerless, the machine problem is solved!

Three minutes to learn how to adjust the main relief valve when excavator is powerless, the machine problem is solved!

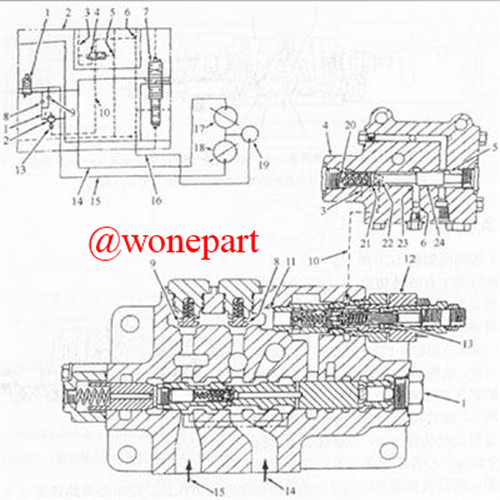

Main relief Valve

Speaking of the main relief valve, even the newly arrived machine is no stranger, enough to see the importance of the valve! It can be said that most of the excavator's inability to move, brakes and other faults are inextricably linked to the valve.

Since the main relief valve is so important, how to accurately determine the fault when the valve is abnormal, and solve the fault accurately by adjusting the main relief valve by itself? Don't worry, the expert will introduce you in detail.

The main relief valve is the highest pressure at which the entire hydraulic system of the excavator is set to operate. When the system pressure exceeds the set pressure of the main relief valve, the main relief valve opens back to the tank oil circuit to overflow the hydraulic oil back to the tank to protect the entire hydraulic system, avoiding excessive oil pressure, resulting in damage to hydraulic components and seals. .

The main relief valve has two sets of set pressure. When the heavy load is required, the excavator needs to be forced to enter the main relief valve through the pilot oil, and the spring setting force is increased for a short time, so that the hydraulic pump power is increased by about 10%. .

Fault phenomenon

Through the action of the main relief valve, it is not difficult to see that if the main relief valve fails, the excavator will appear as a whole without power, braking, or frequent explosion of the hydraulic main pipeline. In this typical case, it is necessary to consider the main overflow. Is there a fault in the flow valve?

Main relief valve adjustment

It is clear that the root cause of the failure phenomenon of the excavator, such as powerlessness and braking, is the main relief valve. We must adjust it in a targeted manner. The adjustment of the main relief valve is divided into two parts. The following bricks explain the specific adjustment steps for everyone:

Adjust the boost pressure in the boost function:

1 Loosen the lock nut "A" and turn the adjusting nut "B" clockwise.

2 Loosen the lock nut "C" and turn the adjusting nut "D" clockwise.

3 After the set pressure is reached, tighten the lock nut “C”.

Main pressure adjustment:

1 Unscrew the adjusting nut "D" counterclockwise.

2 After the set pressure is reached, tighten the lock nut "C".

Note: During the adjustment process, the pressure gauge must be connected and adjusted while observing.

Expert summary:

Among the thousands of parts of the excavator, the main relief valve is not the most important, but it is definitely ‘thick!’ Moreover, in actual work, everyone has to face various abnormal situations that occur in the excavator, so adjusting the pressure of the valve can be said to be a compulsory course for all of your friends!

Of course, experts should also remind everyone that if you are a newcomer, or a friend who has no experience in maintenance, you are not recommended to make adjustments! Because the pressure is raised a little bit, it is easy to cause a tube explosion or damage to the hydraulic components! So everyone must be careful and subtle!