The sealing function of O-ring

The sealing function of O-ring

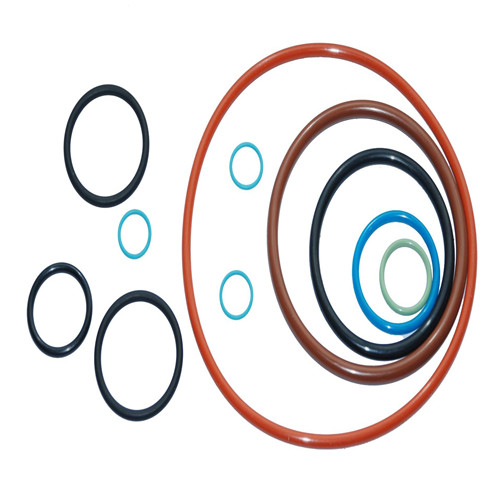

O-ring is a sealing element with a circular cross-section. In the mid-nineteenth century, some people used O-rings made of cast iron as the seals for steam engine cylinders. Later, natural rubber was used for faucets. With the development of rubber production, O-rings are currently made of synthetic rubber. Practice has proved that the sealing performance of the O-ring is very good, so it is used in equipment from airplanes to general hydraulic and pneumatic equipment.

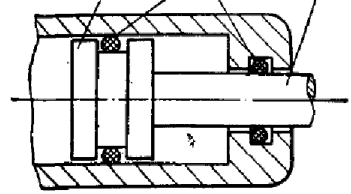

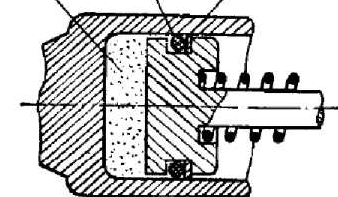

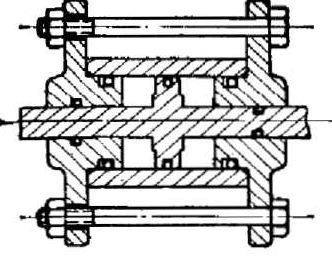

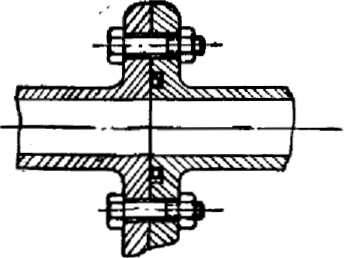

Figure 1-1 shows the installation of an O-ring in a rectangular sealing groove, because the O-ring has a considerable amount of compression during installation (the O-ring is based on the rebound force generated by this compression. Sealing), so this kind of sealing ring is also called "compression sealing ring". Figure 1-2~Figure 1-4 show examples of O-rings used as seals for hydraulic, pneumatic and vacuum equipment.

Compared with other sealing rings, O-rings have the following advantages:

1) The sealing part has simple structure and light weight.

2) Easy to install.

3) The sealing performance is good. When used as a fixed seal, there is almost no leakage. When used as a motion seal, it only leaks when the speed is high.

4) The movement friction is very small.

5) The size and groove have been standardized, which is convenient for use and outsourcing.

Its shortcomings:

1) The frictional resistance at starting is relatively large.

2) Lubricating oil must be added when used as a seal of a pneumatic device, otherwise it is easy to wear.

In view of the above-mentioned shortcomings, in order to make the O-ring work normally, it is necessary to improve the machining accuracy of the O-ring installation part and provide sufficient lubrication.

The material of the O-ring should be selected according to different uses, and the type and proportion of synthetic rubber should be selected appropriately, so that the O-ring can be used in the range of 60~+200°C. The sealing materials generally used in pneumatic, hydraulic, hydraulic and other machinery include butadiene rubber, neoprene rubber, styrene rubber, silicone rubber and fluorine rubber, etc.; used in chemical machinery (the temperature range is +360~—100 °C) sealing ring materials include polytetrafluoroethylene (Teflon) resin, etc.; in space devices that require high temperature resistance and ultra-vacuum and when liquid air is required to be sealed, the sealing ring material cannot use general synthetic rubber. Metal O-rings should be used. Recently, in order to prevent fires, non-flammable phosphate-based hydraulic oils have been used in some hydraulic machines, and ethylene-propylene rubber O-rings suitable for phosphate-based hydraulic fluids have appeared. The operating pressure limit of the O-ring is affected by factors such as operating temperature, movement speed and design. Generally speaking, when a rubber O-ring is used as a fixed seal, its sealing pressure can reach 2000 kg/cm². When used as a motion seal, the sealing pressure can reach 400 kg/cm².

When the O-ring is used under high pressure, in order to prevent damage from being squeezed into the sealing gap, a protective retaining ring made of leather or polytetrafluoroethylene (Teflon) should be used. The material and size of the O-ring and the protective retaining ring and the shape and size of the installation groove are standardized in many countries.

If you have any other detail enquiry or orders, pls feel free to visit our www.wonepart.com/product/o-ring page, then there are more details, email info@Wonepart.com or whatsapp:+86-15860751932.