What is the guide ring or wear ring? What are their functions and precautions?

What is the guide ring or wear ring? What are their functions and precautions?

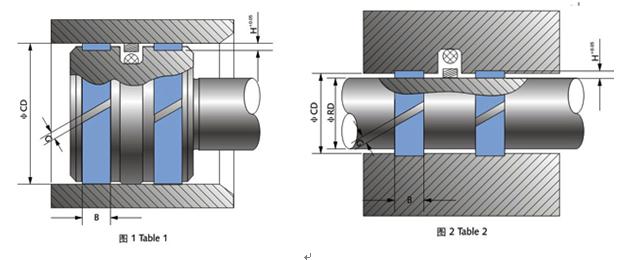

The guide ring or wear ring is mainly used for guiding, and is mainly used for guiding the piston and piston ring in hydraulic cylinders and cylinders, and plays a supporting and guiding role.Guide ring, guide sleeve, support ring, retaining ring, L retaining ring, phenolic cloth guide ring, bakelite electric ring, washer, guide belt.

The guide ring, also called the support ring or wear ring, is a part used on the piston or piston rod of a hydraulic cylinder or cylinder to support the movement of the piston or piston rod. It can prevent the piston or piston rod from directly interacting with the cylinder during movement. Contact and friction play a role in protecting the cylinder and piston or piston rod from damage. The commonly used material for the guide ring is polyoxymethylene (POM).

What is the guiding belt: The guiding belt is a belt-shaped piece that guides the moving part. Its main function is to guide. In order to realize the function of guiding, it must support the guided part and guide and correct its movement trajectory. To achieve the guiding function well, it also requires the isolation, shock absorption and noise reduction of the guiding parts. The guiding belt is mainly used in oil cylinders and air cylinders. Due to its excellent performance, it has also been widely used in other motion mechanisms.

Main requirements:

Support and positioning: the piston and the piston rod are radially supported in the cylinder, and the movement is positioned.

Separation: Separate the piston and cylinder, the piston rod and the guide sleeve of the two pairs of motion pairs to prevent direct scratches, wear and strain between the motion pairs, especially when the motion pairs are all steel parts, they must be separated. Easy to strain.

Anti-friction: Another important function of the guide belt is to reduce the friction and friction work between moving parts. Reduce invalid work and heat.

Vibration absorption and noise reduction: reduce system operation vibration and noise.

Application: Phenolic cloth guide belt has strong carrying capacity. For cylinders with larger partial loads, this guide belt must be installed, such as various heavy-duty cylinders, high-pressure cylinders, large cylinders, and tetrafluoroethylene guide ring or wear ring have low friction coefficient and dirt holding capacity. Strong, practically used in all types of cylinders, especially high-speed cylinders, high-efficiency, low-friction cylinders, and various engineering machinery cylinders.

Note for use: Rolled guide tapes are generally cut as needed before installation. Two issues need to be paid attention to when cutting: angle and length. The angle should be around 45°, and the length should ensure that the opening size meets the standard.

Phenolic plastic is a kind of hard and brittle thermosetting plastic, commonly known as bakelite powder. It has high mechanical strength, toughness and wear resistance, dimensional stability, corrosion resistance, and excellent electrical insulation. It is suitable for making electrical insulation parts for electrical appliances and meters, and can be used in heat and humidity. Use molding performance under conditions

1. The moldability is better, but the shrinkage and directionality are generally larger than that of amino plastics, and contain moisture volatiles. It should be preheated before molding, and exhaust should be exhausted during the molding process. If not, the mold temperature and molding pressure should be increased.

2.The mold temperature has a great influence on the fluidity. Generally, when it exceeds 160 degrees, the fluidity will drop rapidly.

3. The hardening speed is generally slower than amino plastics, and the heat released during hardening is larger. The internal temperature of large thick-walled plastic parts is easy to be too high, which is prone to uneven hardening and overheating. Bakelite guide ring: mainly for guiding.

Wear ring:

Applicable working conditions: It is suitable for guiding the pistons and piston rings in hydraulic cylinders and cylinders, and plays a supporting and guiding role.

Reciprocating speed: ≤15M/S Operating temperature: -60℃~+220℃ Material: PTFE.

Guide ring:

Applicable working conditions: dual-purpose holes and shafts, supporting and guiding the piston or piston rod.

Operating temperature: -60℃~+220℃ Material: PTFE, POM, PA.

L-shaped guide ring:

Applicable working conditions: professional piston, supporting and guiding the piston.

Operating temperature: -60℃~+220℃ Material: PTFE, POM, PA.

T-shaped guide ring:

Applicable working conditions: professional piston, supporting and guiding the piston.

Operating temperature: -60℃~+220℃ Material: PTFE, POM, PA.

Guide sleeve FI:

Applicable working conditions: professional piston, supporting and guiding the piston.

Operating temperature: -60℃~+220℃ Material: PTFE, POM, PA.

Guide sleeve FA:

Applicable working conditions: professional piston, supporting and guiding the piston.

Operating temperature: -60℃~+220℃ Material: PTFE, POM, PA.

Guide sleeve FAI:

Applicable working conditions: professional piston, supporting and guiding the piston, and dust proof.

Operating temperature: -60℃~+220℃ Material: PTFE, POM, PA.

Any wear ring or guide ring enquiry or questions, pls feel free to visit our online web wonepart.com or whatsapp:+86-15860751932 or email info@wonepart.com, we will reply to you soon.