- YD

- China

- 10 days

- 100000 pcs

The engine valve drive mechanism adopts a hydraulic support ball rocker arm structure.

The working principle of the engine is compared with the hydraulic lifter type valve driving mechanism commonly used in gasoline engines today.

The engine brand that we have as following:Cummins, Perkins, Mitsubishi, Caterpillar,VOLVO, Komatsu,Isuzu, Yanmar,Hitachi, DEUTZ, Yuchai, Shangchai, Weichai and so on.

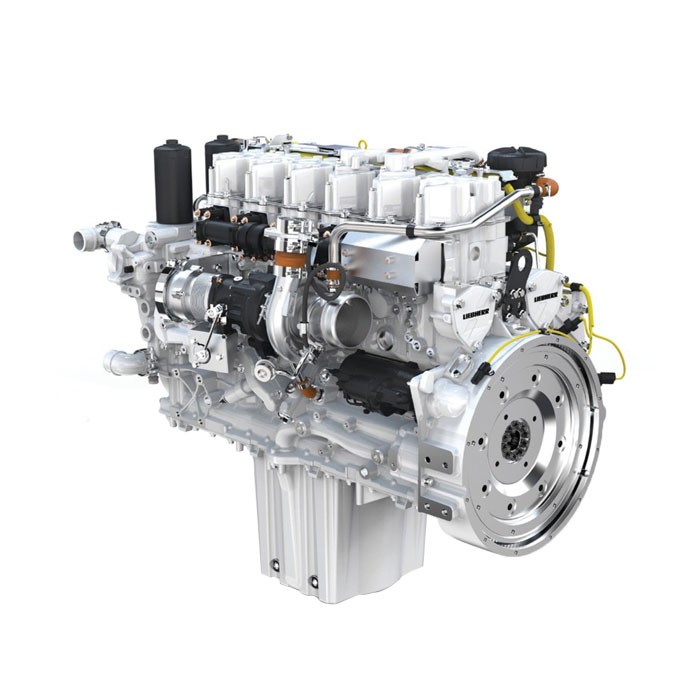

An engine is a machine that can convert other forms of energy into mechanical energy, including, for example, an internal combustion engine (gasoline engine, etc.), an external combustion engine (Stirling engine, steam engine, etc.), an electric motor, and the like. For example, internal combustion engines usually convert chemical energy into mechanical energy. The engine is applicable to both the power generating device and the entire machine including the power unit (eg, gasoline engine, aero engine). The engine was first born in the UK, so the concept of the engine is also derived from English, and its original meaning refers to the kind of "mechanical device that generates power."

Engine Technical characteristics

1. The engine valve drive mechanism adopts a hydraulic support ball rocker arm structure.

The working principle of the engine is compared with the hydraulic lifter type valve driving mechanism commonly used in gasoline engines today. This novel valve driving mechanism has the advantage of relatively small friction torque, so the required driving force is also small, so that it can be effectively reduced. Small engine power consumption reduces fuel consumption.

2. In order to effectively reduce the weight of the whole vehicle, the 1.4-liter gasoline engine adopts an aluminum alloy cylinder, which has achieved a very obvious lightweight effect.

3. The special metal material and special plastic processing air intake pipe are used to replace the traditional metal air intake pipe, which not only receives the lightweight effect, but also can effectively reduce the intake pipe wall resistance, improve the intake efficiency and increase the engine power.

4. The cutting-type connecting rods processed by advanced technology are used to cut the large-end holes of the processed connecting rods with special breaking equipment, instead of the sawing and grinding process originally used. This makes it possible to use the saw-toothed "Huff" face of the break link to ensure an absolutely accurate fastening position, thereby reducing friction and extending the life of the link.

5. The hot-sleeve camshaft can not only reduce the weight of the camshaft, but also achieve higher cam profile accuracy and more accurate valve timing than the original camshaft.

6. The throttle adopts electronic control device, also known as E-GAS electronic throttle. This control device can uniformly coordinate and reasonably manage the instantaneous requirements of engine torque and output power under various working conditions of the vehicle, such as driver's acceleration, overtaking, and starting air conditioning. In this way, the operating state of the engine at each operating point is always in the optimal range, which can meet the requirements of low emission and low fuel consumption, and optimize the driving performance of the whole vehicle.

7. Improve the arrangement position of the engine intake system, which can effectively reduce the intake air temperature of the engine and increase the intake air density, so that the engine can output more power on the basis of the increase of the charging efficiency. The specific improvement is to arrange the intake pipe of the engine on the left side of the engine front end module and above the cooling water tank.

8. In order to improve the anti-corrosion ability of the cooling water tank and prolong the service life of the water tank, the cooling water tank fins arranged in the front end module of the engine are covered with plastic.

9. In order to prevent the engine oil pan from colliding with the uneven bottom surface and causing damage to the engine, a metal shield can be optionally installed under the oil pan.

10. In order to effectively insulate, sound-proof and isolate the earthquake, it will not be transmitted into the passenger compartment to affect the ride comfort. An insulated shield plate is installed in the exhaust pipe.

The engine brand that we have as following:

Cummins, Perkins, Mitsubishi, Caterpillar,VOLVO, Komatsu,Isuzu, Yanmar,Hitachi, DEUTZ, Yuchai, Shangchai, Weichai and so on.