- NOK

- Japan

- 10 days

- 100000 pcs

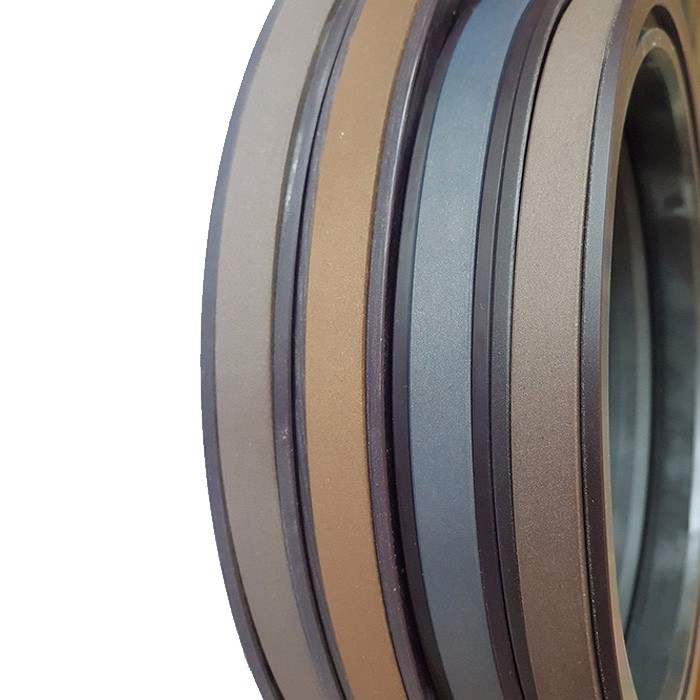

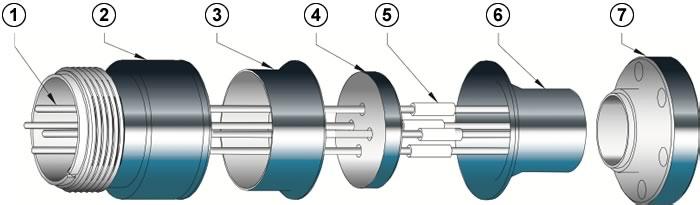

The boned seal is a rubber ring and a metal ring integrally bonded and vulcanized, and is a sealing ring used to seal the thread and flange connection. The ring includes a metal ring and a rubber gasket.

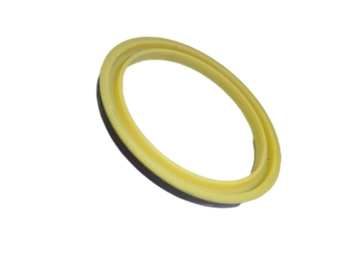

Anti-rust treatment of metal rings, rubber rings generally use oil resistant nitrile rubber or fluorine rubber. The combination pads are available in metric and inch sizes. There are standard JB982-77 regulations for the combination of metal pads and rubber in combination pads. Combination gaskets are used for threaded pipe joints and screw plugs. It is generally used with ferrule pipe joints to block oil ports. It is mainly used for static sealing of end faces of threaded joints of hydraulic valve pipe joints.

Bonded Seal

Bonded Seal are dust seals for oscillating and rotating movement for hing pin and bush. Bonded seal can be used under severe dust conditions to improve the durability of the equipment. Relief effect ease the process of draining used grease when filling up new

The boned seal is a rubber ring and a metal ring integrally bonded and vulcanized, and is a sealing ring used to seal the thread and flange connection. The ring includes a metal ring and a rubber gasket.

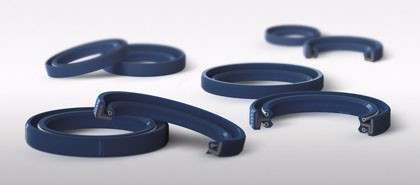

Boned seals basic information

Anti-rust treatment of metal rings, rubber rings generally use oil resistant nitrile rubber or fluorine rubber. The combination pads are available in metric and inch sizes. There are standard JB982-77 regulations for the combination of metal pads and rubber in combination pads. Combination gaskets are used for threaded pipe joints and screw plugs. It is generally used with ferrule pipe joints to block oil ports. It is mainly used for static sealing of end faces of threaded joints of hydraulic valve pipe joints. It is applicable to British and American standards The static sealing of the end face of the joints of British threads and French and German standard metric threads. The combined sealing gasket can be divided into A type and B type according to the structural form; it can be divided into all-inclusive and half-inclusive according to the difference of the rubber.

Based on NOK standard, Bonded seals including ODI,OSI,OUIS,OUHR,OKH,SPGO,SPG,SPGM,SPGN,SPGW,SPGC,CPI,CPH

Purpose

It is suitable for the pipeline system of oil as the medium, used for welding, ferrule, expansion pipe joints, screw plugs and mechanical systems to seal the pressure system, in order to prevent oil, fuel, water and chemicals from leaking. Because of its simple structure, efficient sealing, and low price, it is widely used in machinery manufacturing.

Technical data

Working pressure: ≤40 Mpa

Temperature: -25 ℃ ~ + 100 ℃

Medium: hydraulic oil

Material properties

Material: rubber, metal

Specification | OD | ID | Thickness | Tolerance | Glue Thickness | Specification | OD | ID | Thickness | Tolerance | Glue Thickness |

+0.13 | ±0.13 | ±0.13 | +0.13 | ±0.13 | ±0.13 | ||||||

-229 | 24.00 | 16.70 | 1.50 | +/-0.10 | 0.85 | -310 | 17.00 | 10.70 | 1.50 | +/-0.10 | 0.70 |

-230 | 24.00 | 17.40 | 1.50 | +/-0.10 | 0.90 | -312 | 18.10 | 11.80 | 1.50 | +/-0.10 | 0.65 |

-231 | 24.70 | 18.00 | 1.50 | +/-0.10 | 1.05 | -313 | 19.00 | 12.70 | 1.50 | +/-0.10 | 0.70 |

-232 | 26.00 | 18.70 | 1.50 | +/-0.10 | 0.85 | -315 | 20.10 | 13.80 | 1.50 | +/-0.10 | 0.70 |

-233 | 28.00 | 20.70 | 1.50 | +/-0.10 | 0.90 | -316 | 21.00 | 14.70 | 1.50 | +/-0.10 | 0.70 |

-234 | 28.70 | 21.50 | 2.50 | +/-0.10 | 0.90 | -317 | 23.00 | 16.70 | 1.50 | +/-0.10 | 0.70 |

-235 | 28.00 | 22.50 | 1.50 | +/-0.10 | 0.90 | -319 | 23.90 | 17.20 | 2.10 | +/-0.10 | 0.75 |

-236 | 30.00 | 22.70 | 2.00 | +/-0.10 | 0.85 | -320 | 27.00 | 18.70 | 2.00 | +/-0.10 | 0.85 |

-237 | 30.00 | 22.70 | 3.00 | +/-0.15 | 0.85 | -321 | 29.00 | 20.70 | 2.00 | +/-0.10 | 0.85 |

-238 | 32.00 | 24.70 | 2.00 | +/-0.10 | 0.85 | -324 | 31.00 | 22.70 | 2.00 | +/-0.10 | 0.85 |

-239 | 35.00 | 26.70 | 2.00 | +/-0.10 | 0.85 | -325 | 32.00 | 23.70 | 2.00 | +/-0.10 | 0.85 |

-240 | 36.00 | 27.20 | 2.00 | +/-0.10 | 0.90 | -326 | 33.00 | 24.70 | 2.00 | +/-0.10 | 0.85 |

-241 | 37.00 | 28.70 | 2.00 | +/-0.10 | 0.85 | -327 | 35.30 | 27.00 | 2.00 | +/-0.10 | 0.85 |

-242 | 39.00 | 31.00 | 2.00 | +/-0.10 | 1.00 | -328 | 36.00 | 27.70 | 2.00 | +/-0.10 | 0.85 |

-243 | 42.00 | 33.70 | 2.00 | +/-0.10 | 1.05 | -329 | 36.00 | 28.60 | 2.00 | +/-0.10 | 0.85 |

-244 | 43.00 | 34.30 | 2.00 | +/-0.10 | 1.05 | -330 | 37.50 | 29.20 | 2.00 | +/-0.10 | 0.85 |

-245 | 46.00 | 36.70 | 2.00 | +/-0.10 | 1.05 | -331 | 39.00 | 30.70 | 2.00 | +/-0.10 | 0.85 |

-246 | 51.00 | 40.00 | 2.50 | +/-0.10 | 0.95 | -332 | 42.00 | 33.70 | 2.00 | +/-0.10 | 0.85 |

-247 | 53.00 | 42.70 | 3.00 | +/-0.15 | 0.85 | -333 | 48.00 | 37.00 | 2.50 | +/-0.15 | 1.30 |

-248 | 59.00 | 48.70 | 3.00 | +/-0.15 | 1.05 | -334 | 51.00 | 40.00 | 2.50 | +/-0.15 | 1.30 |

-249 | 60.00 | 52.00 | 3.00 | +/-0.15 | 1.05 | -335 | 54.00 | 43.00 | 2.50 | +/-0.15 | 1.30 |

-250 | 64.50 | 53.30 | 3.00 | +/-0.15 | 1.05 | -336 | 57.00 | 46.00 | 2.50 | +/-0.15 | 1.30 |

-251 | 73.00 | 60.70 | 3.00 | +/-0.15 | 1.15 | -337 | 60.00 | 49.00 | 2.50 | +/-0.15 | 1.30 |

-252 | 79.50 | 68.60 | 3.50 | +/-0.15 | 1.75 | -510 | 14.70 | 10.40 | 1.25 | +/-0.10 | - |

-253 | 90.30 | 76.08 | 3.38 | +/-0.15 | 1.51 | -511 | 18.70 | 13.35 | 1.25 | +/-0.10 | - |

-254 | 101.48 | 89.09 | 3.25 | +/-0.15 | 1.50 | -512 | 22.70 | 17.35 | 1.25 | +/-0.10 | - |

-255 | 143.67 | 127.00 | 5.00 | +/-0.15 | 1.50 | -513 | 26.70 | 21.35 | 1.25 | +/-0.10 | - |

-301 | 7.50 | 3.60 | 1.00 | +/-0.10 | 0.70 | -514 | 32.60 | 27.30 | 1.25 | +/-0.10 | - |

-302 | 9.00 | 4.60 | 1.00 | +/-0.10 | 0.70 | -515 | 39.50 | 34.20 | 2.00 | +/-0.10 | - |

-303 | 10.00 | 5.60 | 1.00 | +/-0.10 | 0.70 | -516 | 49.60 | 42.20 | 2.00 | +/-0.10 | - |

-304 | 11.00 | 6.60 | 1.00 | +/-0.10 | 0.70 | -517 | 55.50 | 48.70 | 2.00 | +/-0.10 | - |

-305 | 13.27 | 6.85 | 1.30 | +/-0.10 | 0.57 | -518 | 68.50 | 60.50 | 2.00 | +/-0.10 | - |

-306 | 11.40 | 7.00 | 1.00 | +/-0.10 | 0.70 | -519 | 12.70 | 8.30 | 1.25 | +/-0.10 | - |

-307 | 13.00 | 8.60 | 1.00 | +/-0.10 | 0.70 | -520 | 32.60 | 27.30 | 2.00 | +/-0.10 | - |